Function on a Belt Conveyor

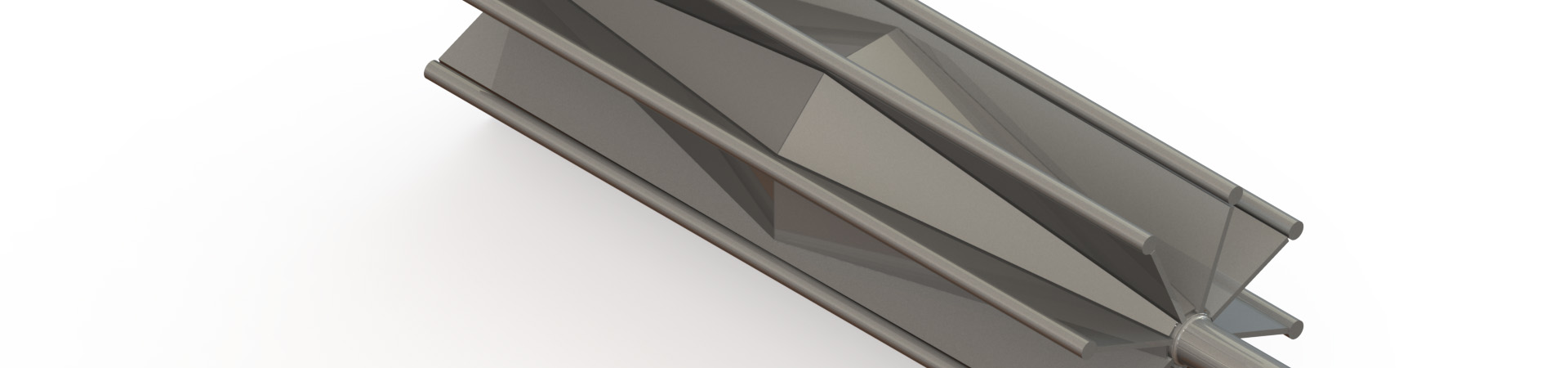

The Wing pulley is designed for conveyors transporting materials that tend to stick to the belt. Its beating action, as the belt passes over it, facilitates the progressive detachment of the transported materials.

This functionality is particularly important in humid environments, where the adhesion and clumping of materials on the belt are increased. This type of pulley helps ensure efficient system operation while reducing interruptions caused by material build-up.

Like the squirrel cage pulley, the wing pulley or beater bar pulley is equipped with conical plates welded to the shaft, allowing detached materials to be discharged to the sides of the conveyor. This design reduces the risk of clogging and minimizes maintenance needs, thereby enhancing the overall efficiency of the system.

Solutions Tailored to Every Need

A specialist in conveyor pulley manufacturing for over 25 years, ALTEMA designs custom solutions tailored to a wide range of industrial needs. While special pulleys like the wing pulley or beater bar pulley address specific constraints, we also manufacture more conventional pulleys, such as drive pulleys, essential for moving the conveyor belt, or return pulleys, which play a key role in redirecting and tensioning the belt.

Each conveyor pulley manufactured by our teams undergoes rigorous quality control, ensuring reliable and durable products that are perfectly suited to the technical and economic requirements of our industrial clients.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

Technical Support in Defining Your Special Pulleys

ALTEMA has extensive experience in the manufacture of Conveyor belt pulleys for demanding sectors such as quarries. This enables us to support our customers and partners on a daily basis to ensure excellent value for money and a product perfectly designed for its application. The aim is to ensure perfect adaptation of the beater drum to the conveyor belt assembly, guaranteeing the reliability of the whole system.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Other specific drum pulleys

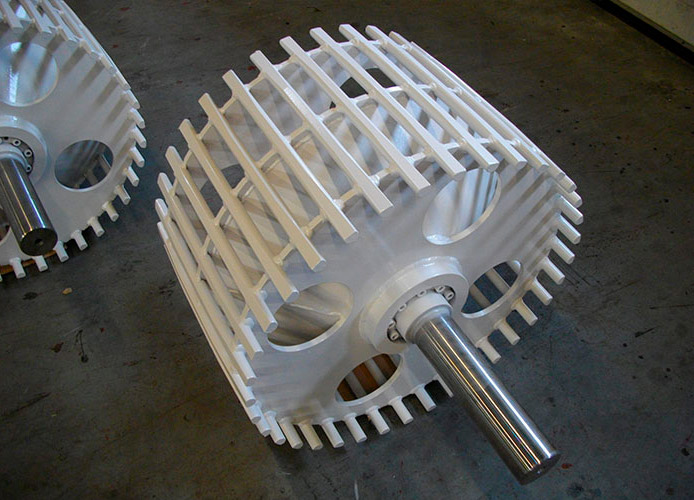

Self cleaning pulley

The self cleaning pulley is manufactured with bars welded to the side flanges instead of the tube as on a standard drum.

Idler pulley & Conveyor roller

To meet specific needs on belt conveyors, ALTEMA can manufacture customized Idler drum pulleys, also known as conveyor rollers.

Custom-made pulleys

Custom-made drum pulleys are produced on the basis of drawings supplied by customers, and can also be modeled in the design office.