FUNCTION AND BUSINESS SECTORS

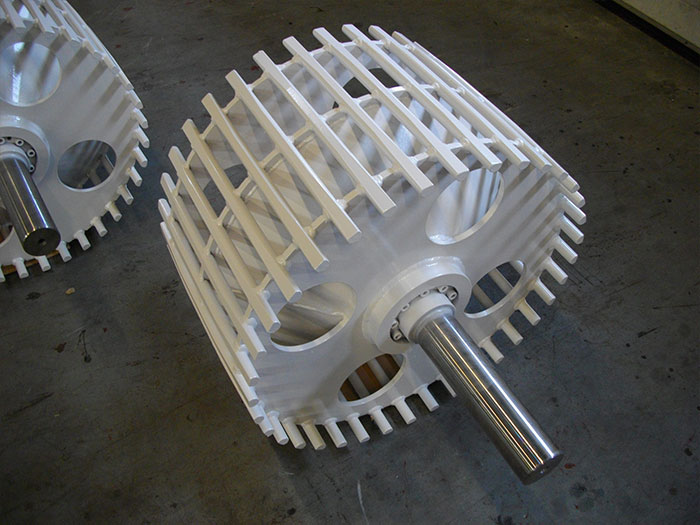

Self cleaning pulleys or Cage drum pulleys are conveyor drums manufactured with bars welded to the side flanges instead of the tube as on a standard drum. The main advantage of self cleaning pulley is that they prevent product caking and retention between the belt and the drum tube. The product drains through the bars directly into the drum.

At ALTEMA, cage pulleys are mainly used in the food industry, handling dry matter, cereals, grains and wheat. This type of self-cleaning drum pulley is also found in the quarrying sector and used on sand and gravel pits. The self cleaning pulley is generally installed in silos and elevators.

Implementation

There are 2 designs for the cage drum pulley.

- Standard design: The drum pulley is equipped with flanges on each side of the drum, which are manufactured with large openings to allow product overflow as it enters the drum.

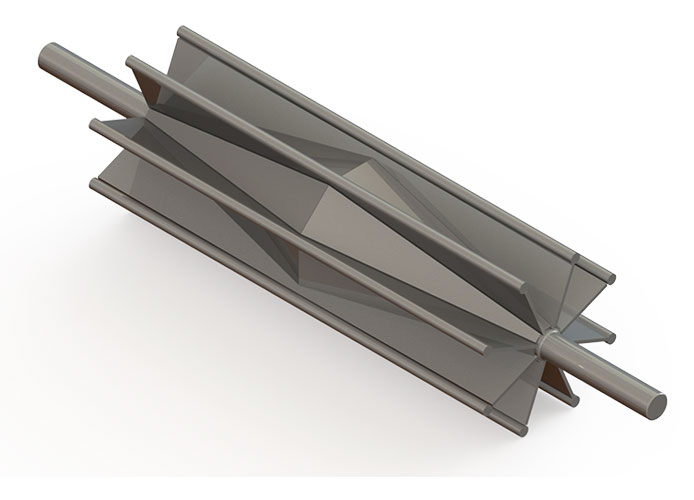

- Design with discharge cone: The design is different in that cones are attached to the inside of the drum to facilitate product discharge from the sides.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

Manufacturing methods cage pulley

There are 3 types of bars installed on the cage pulley :

- The ALTEMA standard for the manufacture of squirrel-cage drums: the welding of round bars to the flanges.

- The use of square bars instead of round ones.

- Rectangular dishes can also be welded.

Depending on the type of bars installed, and when they need to be curved, two options are possible: either the whole assembly is machined curved after assembly, or the bars are curved before (or during) installation and welding.

TECHNICAL SUPPORT INDEFINING YOUR PRODUCTS

Present on the market for 25 years, ALTEMA is the specialist in the construction of cage conveyor belt pulley for numerous sectors of activity, such as quarries. ALTEMA supports its customers on a daily basis to certify the perfect price-quality ratio. Every technical solution is designed to ensure optimum use of the cage pulley. This means seamless integration into its environment, taking into account the specific features of each application.

Altema services

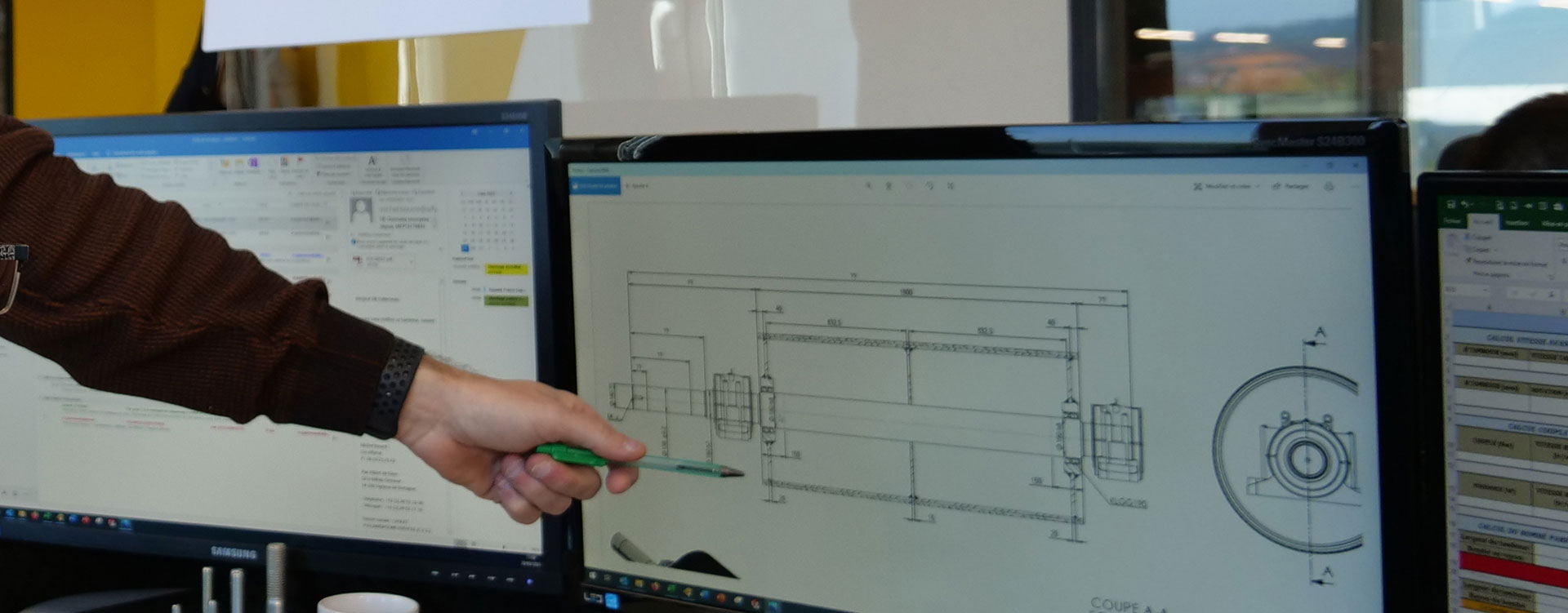

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Other specific drum pulleys

Wing pulley

A wing pulley is positioned on a conveyor when it is transporting a material that will tend to stick to the conveyor belt.

Idler pulley & conveyor roller

To meet specific needs on belt conveyors, ALTEMA can manufacture customized Idler drum pulleys, also known as conveyor rollers.

Custom-made drum pulleys

Custom-made drum pulleys are produced on the basis of drawings supplied by customers, and can also be modeled in the design office.