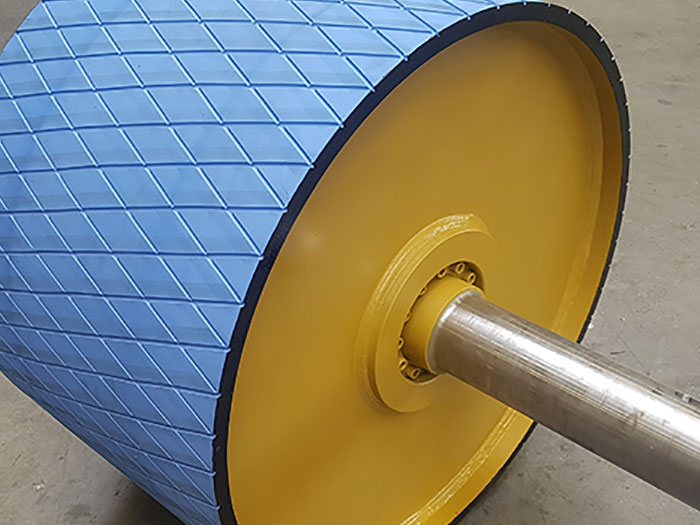

Elevator drum pulley for bulk handling

In 90% of cases, a tail or a return pulley is a Squirrel Cage pulley or Self-cleaning pulley In fact, they are usually installed to handle bulk materials, such as cereals in the agricultural sector. Installed in a vertical bucket elevator, the tail pulley is at the bottom. Part of the conveyed material therefore falls back onto the drum pulley. The Cage pulley design prevents product agglomeration. In this case, the evacuation cone design also prevents retention by evacuating the material on both sides.

Cage drum pulley execution

There are 2 ways to design a cage pulley :

- The so-called standard design comprises two flanges with large holes on each side and a cylindrical “surface” made up of bars, allowing the material to pass through. This then drains through the holes in the flanges.

- The other design is identical in terms of the bars, but also includes a discharge cone at the pulley shaft to aid product discharge.

three methods for installing the bars:

- Round bars welded to the flanges of squirrel cage pulley

- Square bars

- Rectangular steel plates

In all 3 cases, the cage drum pulley can be machined in a curved shape (or the bars are bent when technically possible).

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

A recognized player in the manufacture of squirrel cage pulleys for demanding sectors such as food processing, ALTEMA assists its customers every day to guarantee the best technical and economic compromise. Each cage pulley is tailored to its specific use and purpose. The aim is to ensure the perfect fit of the pulley on the conveyor or elevator, while improving its longevity.

Altema services

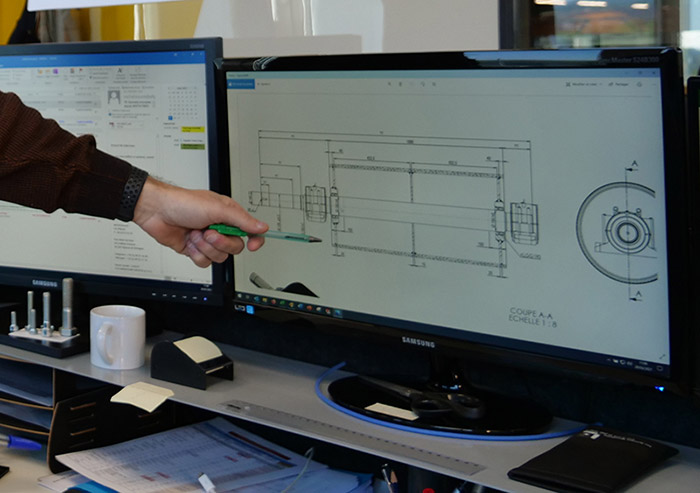

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

CLASSIC ELEVATOR PULLEY

ALTEMA manufactures drum pulleys for silos and bucket elevators for the port, food processing and agricultural sectors.

LARGE-DIAMETER ELEVATOR PULLEY

ALTEMA manufactures elevator drum pulleys with diameters of up to 1,300 mm for installations requiring high-speed conveying.