Elevator pulleys for all bulk handling sectors

ALTEMA manufactures drum pulleys for silos and bucket elevators (elevator pulleys) for the port, food processing and agricultural sectors. Most standard elevator drum pulleys are composed of one tube and two flanges. They are mainly used as drive or head pulleys. More occasionally, a tail or return pulley may also be composed of one tube and two flanges (instead of a cage pulley).

A WIDE RANGE OF PULLEY SIZES

ALTEMA can cover a wide range of dimensions in the manufacture of bare steel drum pulleys for industrial Elevators. Each elevator drum pulley can be bare or lined, and fitted with various types of connections between the flanges and the shaft: shrink discs, UCFC flanged bearings and removable hubs.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

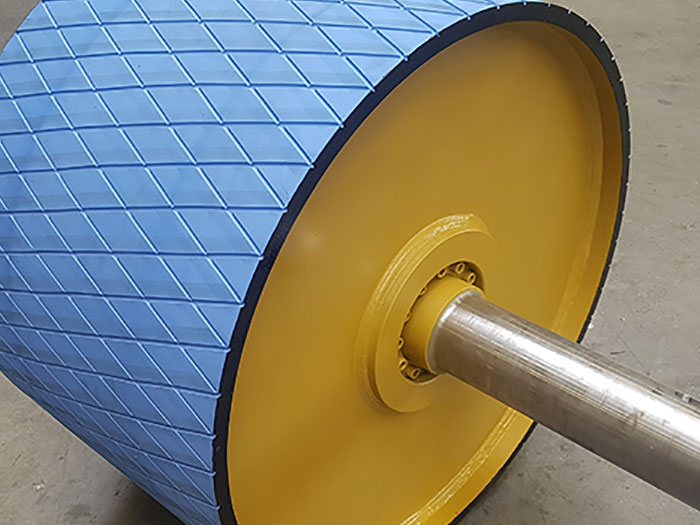

Lagging for handling pulleys

Classic pulleys can be supplied bare or with any type of coating. For each application, ALTEMA’s technical teams can help you define the best suited lagging to your needs. For the agri-food sector, specific laggings such as blue nitrile can also be installed by our teams.

TECHNICAL SUPPORT INDEFINING YOUR PRODUCTS

For over 25 years, ALTEMA has specialized in the construction of bare pulleys and elevator pulleys for sectors such as the food industry. This experience enables the company to assist its partners on a daily basis to ensure the perfect price-quality ratio, fully adapted to the use of the conveyor pulley. The aim is to guarantee a perfect fit of the pulley on the conveyor belt assembly, while improving reliability.

Altema services

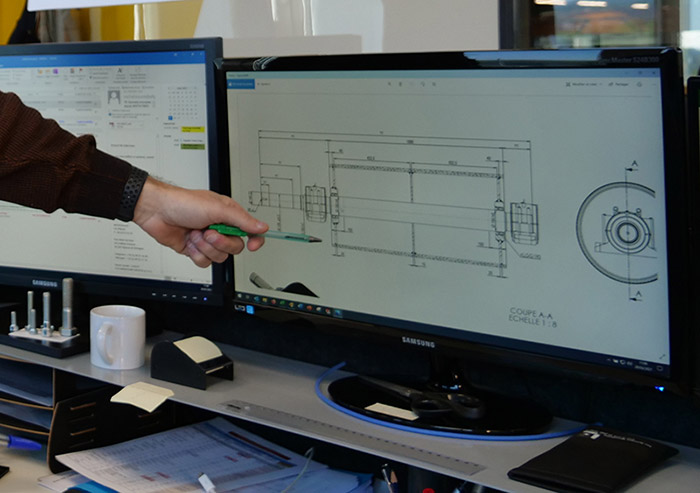

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

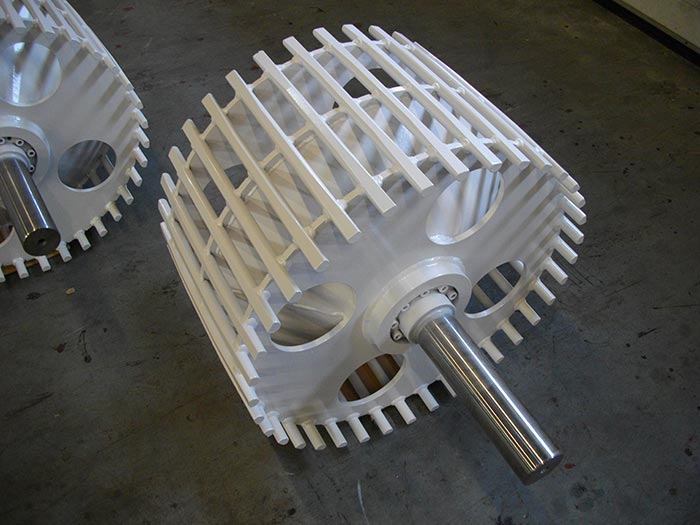

ELEVATOR CAGE PULLEY

A cage drum pulley or self-cleaning pulley is manufactured with bars welded to the side shields instead of the tube as on a standard pulley.

LARGE-DIAMETER ELEVATOR PULLEY

ALTEMA manufactures pulleys with diameters of up to 1,300 mm for installations requiring high-speed conveying.