Elevator Drum Pulleys for every function

ALTEMA offers a wide range of solutions for every application, whether in the food industry or in port areas. Whether in steel or stainless steel, with or without lining, ALTEMA can advise you on which belt bucket elevator pulley is best suited to your application.

ALTEMA offers a wide range of technical solutions for bi-curved or cylindrical, smooth or rubberized handling drum pulleys. Various types of connections are available for these conveyor pulleys: welded, shrink disc, VECO-BLOC hubs and flanged bearings. A elevator drum pulley is used on bucket elevators, belt elevators or as a drive in conveyor systems.

ALTEMA’s production facilities and industrial organization are extremely flexible, enabling us to produce all types of elevator drum pulley in record time, in strict compliance with specifications. Since 1995, ALTEMA has acquired considerable experience in the field of materials handling and the manufacture of bucket elevator pulley. Thanks to this long experience, ALTEMA is able to offer a wide range of products and solutions. All components are made from high-quality materials. This guarantees a long service life and also facilitates maintenance.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

CLASSIC ELEVATOR DRUM PULLEY

ALTEMA manufactures drum pulleys for silos and bucket elevators for the port, food processing and agricultural sectors.

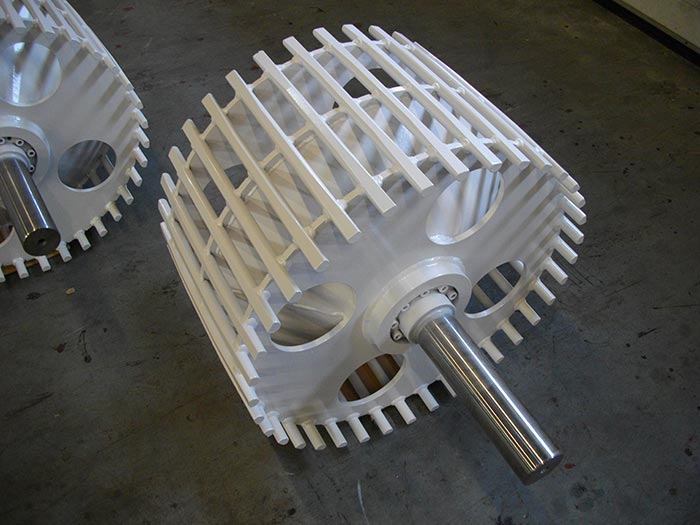

Elevator Cage pulley

A Squirrel cage pulley or Slatted pulley is a drum pulley manufactured with bars welded to the side plates instead of the tube as on a standard pulley.

Large-diameter Elevator pulley

ALTEMA manufactures elevator pulleys with diameters of up to 1,300 mm for installations requiring high-speed conveying.

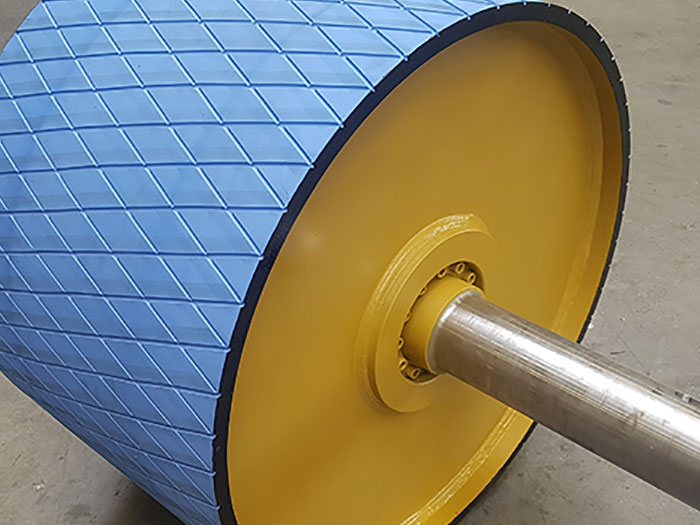

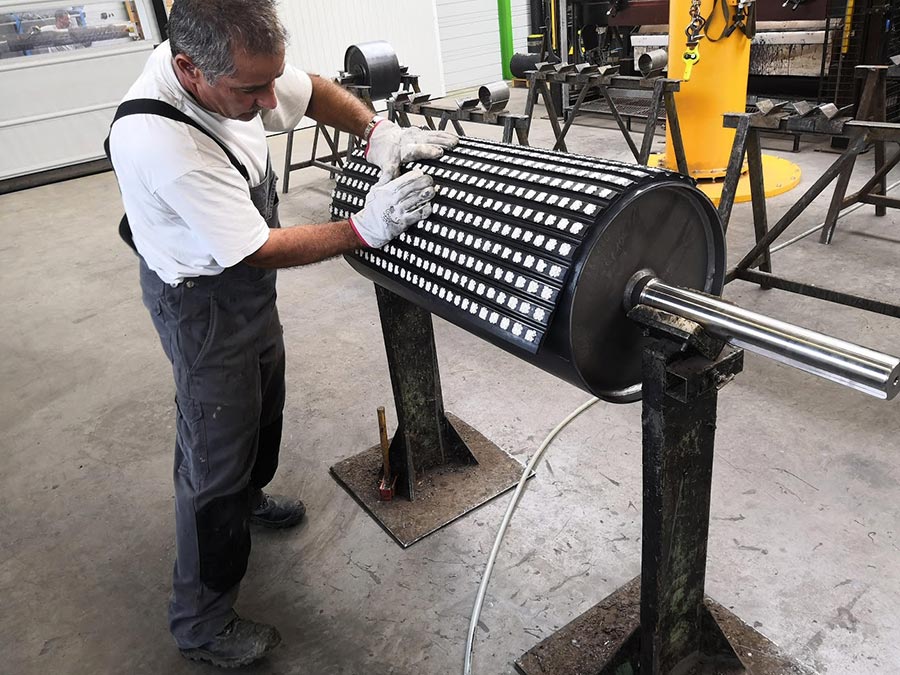

Laggings on industrial drum pulleys

ALTEMA can equip any elevator drum pulley with any type of lagging. Each application requires its own type of lagging. ALTEMA’s teams can help you define the type and process that will enable the industrial drum pulley to perform its function in the best possible way. For applications in the food industry, these rubber coatings are available in appropriate colors according to their specification: white, blue, pink, etc. For transporting food products, silicone rubber is FDA-compliant and 100% approved for this use.

CONNECTING SYSTEMS for bucket elevator drums

ALTEMA offers a variety of connections between the shaft and the flanges: removable vecobloc hub or shrink disc, UCFC flange bearing or welded connection to the flange.

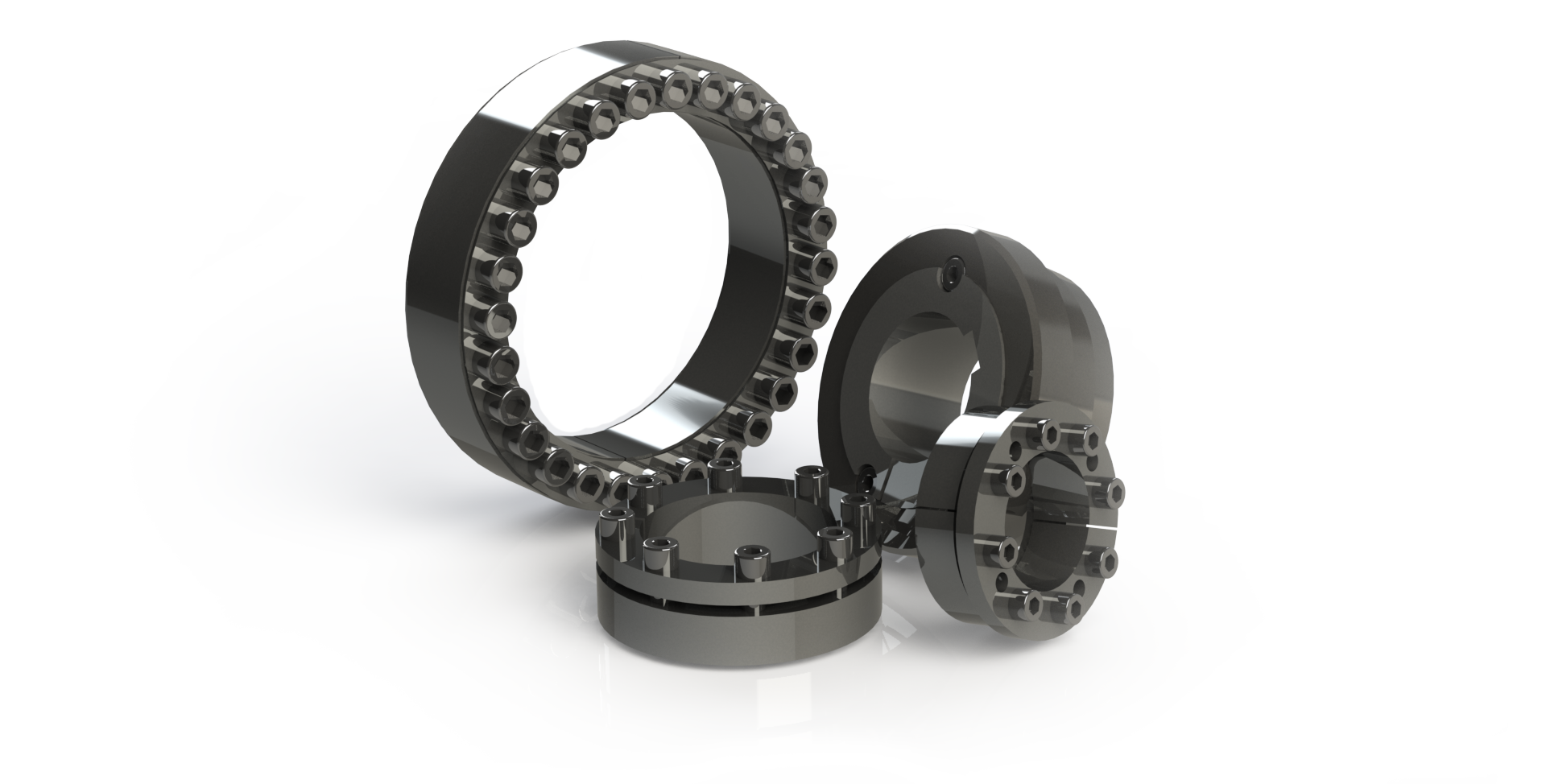

CLAMPING RINGS

The shrink disc’s operating principle is based on the radial deformation of the frustoconical parts that form its head. The torque applied to the screw causes an axial movement of these parts, which, due to their conicity, come into contact with each other and generate a pressure force. The advantages of shrink discs are that they eliminate gap between the drum and shaft, and distribute the drum pulley load evenly over the entire shaft diameter.

VECOBLOC UNIVERSAL HUBS

VECOBLOC removable hubs, also known as TAPERLOCK hubs, are the most practical system for securing the bucket elevator pulley to its shaft without the need for special tools. ALTEMA offers a wide range of removable hubs to meet all requirements. This solution offers users an alternative to shrink discs when they wish to retain a keyed connection.

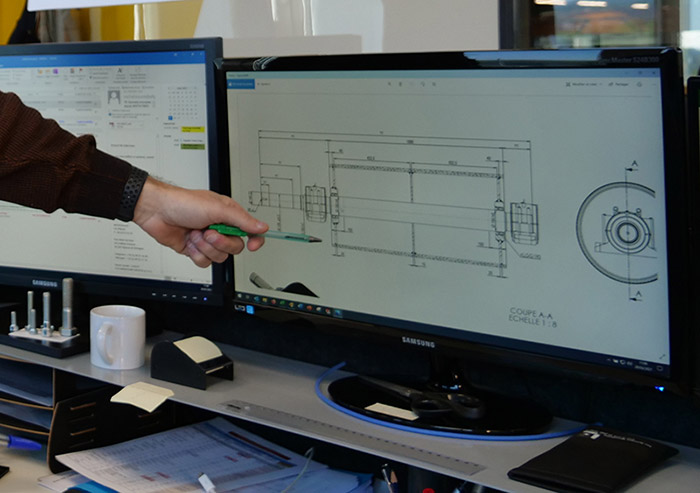

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

ALTEMA, a leading manufacturer of conveyor belt drums and pulleys, supports its customers on a daily basis in defining the best technical choices for the design and manufacture of their conveyor belt pulleys. Our aim is to provide all our customers with personalized support, ensuring excellent value for money and a product perfectly suited to its function and purpose.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.