Oversized Conveyor pulleys

Whether for bulk conveying in the mining and quarrying sectors, or for installations requiring high throughput, ALTEMA manufactures conveyor drums up to 1,300mm in diameter. ALTEMA regularly manufactures drum pulleys for customers worldwide with diameters of Ø609mm, Ø813mm, Ø1016mm and Ø1250mm.

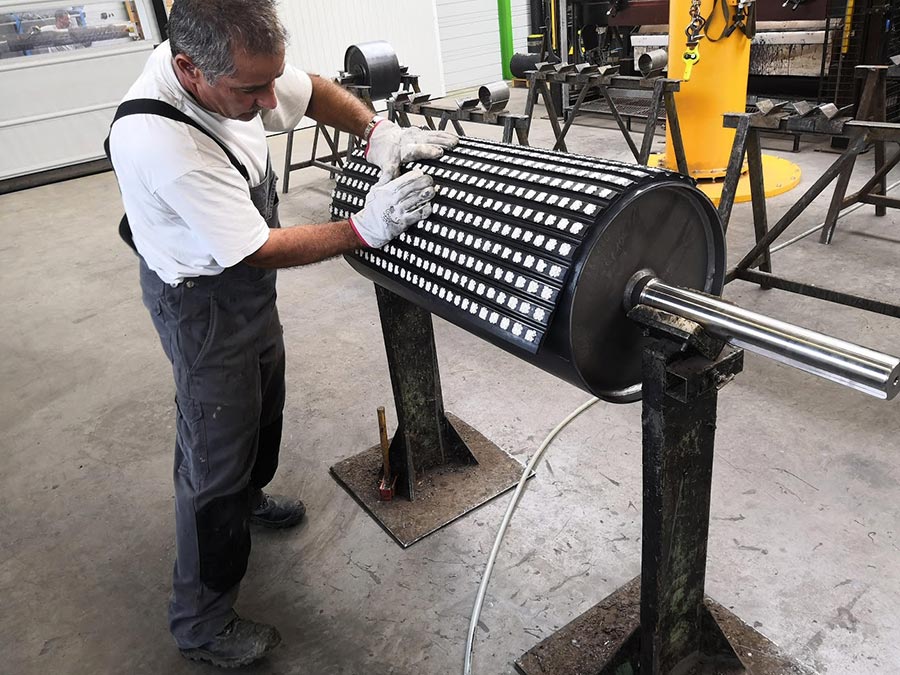

Manufacturing a large diameter or heavy duty drum pulley requires a different approach. Compared to conventional conveyor pulleys, handling phases have to be anticipated, as well as specific assembly tools. ALTEMA is equipped with large lathes for machining drum pulleys up to 1300mm in diameter and 6 meters in length. The workshops are also equipped with heavy-duty overhead cranes for handling these large conveyor drums. ALTEMA can machine shafts up to a diameter of 300mm inside the drum pulley, turned down to Ø260mm at the bearing.

The manufacture of large industrial drum pulleys also requires special expertise in the assembly of large SN and plummer block bearings. ALTEMA has the tools and know-how to apply coatings to these large conveyor belt pulleys using manual gluing.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

Laggings for oversized drums

ALTEMA can equip large and heavy-duty conveyor pulleys with any type of coating. Each application requires its own type of lagging. ALTEMA’s teams can help you define the type of lagging and the process that will best enable the drum pulley to perform its function.

CONNECTING SYSTEMS for heavy duty conveyor pulleys

ALTEMA conveyor pulleys can be fitted with various types of shaft/flange connections, such as Vecobloc hubs, shrink discs, bearings…

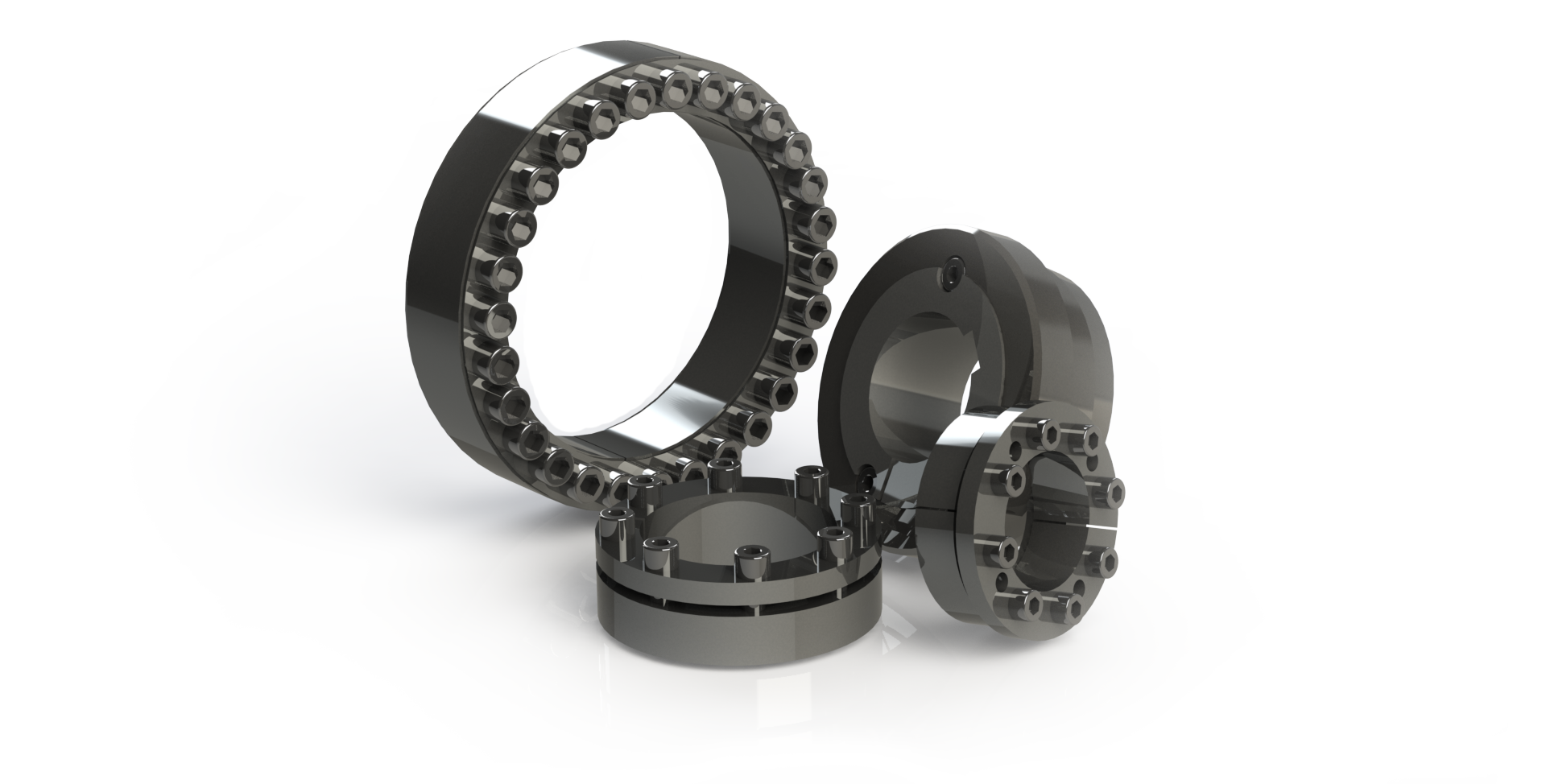

CLAMPING RINGS

The shrink disc system works by radially deforming frustoconical parts. This radial deformation creates a clamping force that prevents axial movement.

VECOBLOC UNIVERSAL HUBS

ALTEMA offers VECOBLOC removable hubs. This system is used to secure the flange + tube assembly of the “industrial drum pulley” to its shaft without the need for special tools. ALTEMA offers a wide range of removable hubs to meet all requirements. This solution offers users an alternative to clamping brackets.

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

ALTEMA is a leading manufacturer of Heavy duty Drum pulleys for a wide range of industries. The company works closely with its customers on a daily basis to ensure the perfect price-quality ratio, tailored to the purpose of the handling drum pulley. The aim is to ensure that the large-diameter conveyor pulley is perfectly matched to the conveyor belt assembly, guaranteeing its longevity.

Altema services

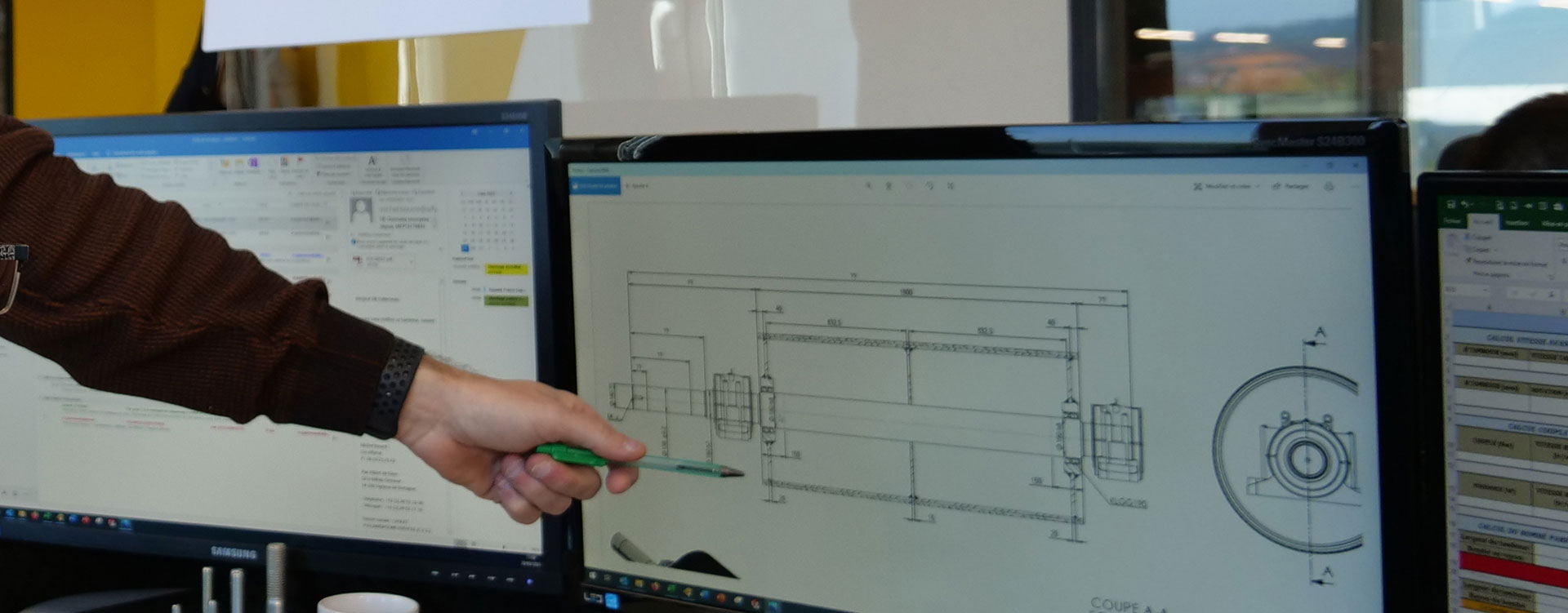

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.