Conveyor pulley lagging for applications with very high tensile forces

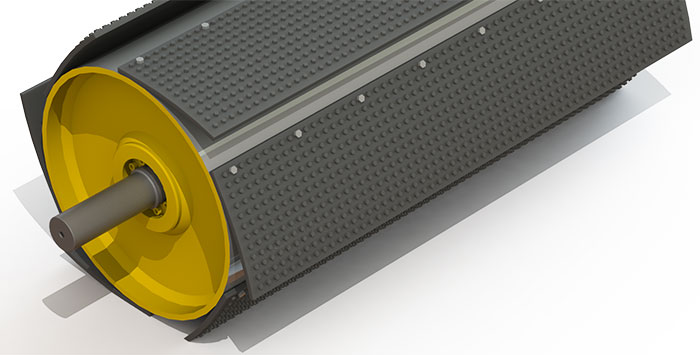

The Slide Lag® coating system is a drum lagging system that uses welded slides on the drum surface as a base for the lagging. The covering consists of vulcanized rubber on a steel support that slides under the rails. Slide Lag® lagging does not require drum or belt disassembly, reducing handling and transport times and making it more economical.

Slidelag® lagging is applied by a high-pressure hot vulcanization process, using thick steel plates designed to fit each drum diameter. Its elastomer composition enables the head pulley or drive drum to achieve high tensile strength. This lagging can be replaced without removing the drum pulley from the conveyor.

In addition, EDGE-CROWN elements can be used to quickly transform the profile of the conveyor pulley to obtain the crowning. This crowning, with a 4mm radius, centers the belt.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Other profile types

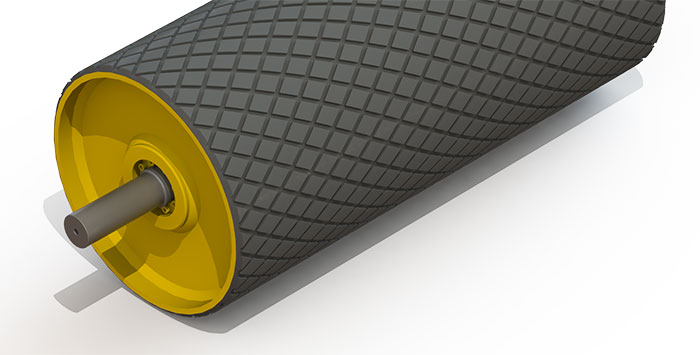

Diamond

The universal lagging

Used on bend pulley and take up pulley. It is also suitable for head pulley.

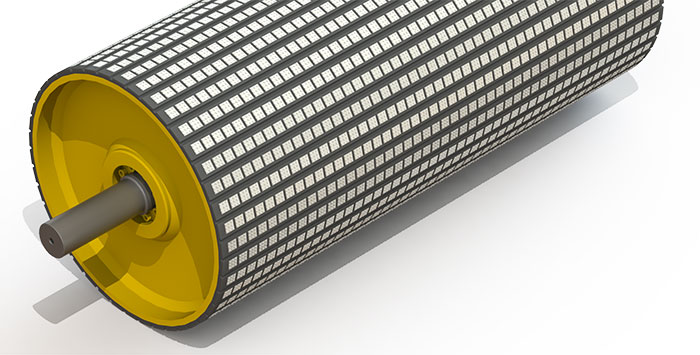

Ceramics

The high-adhesion lagging

Effective in humid environments to prevent slipping on the conveyor belt.

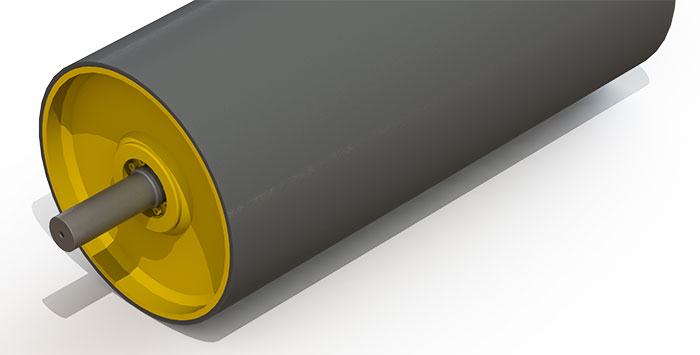

Smooth

Protective lagging

For conveyor pulleys that don’t drive the belt, to extend their service life.

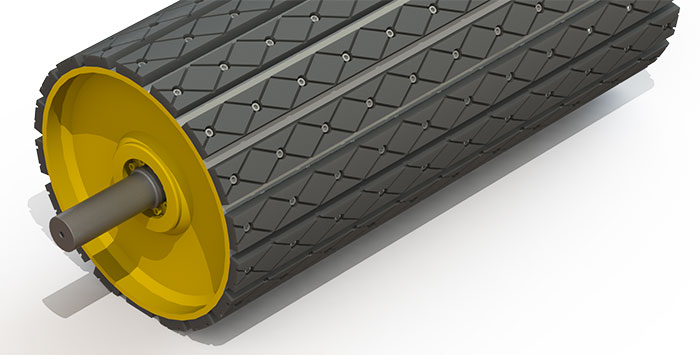

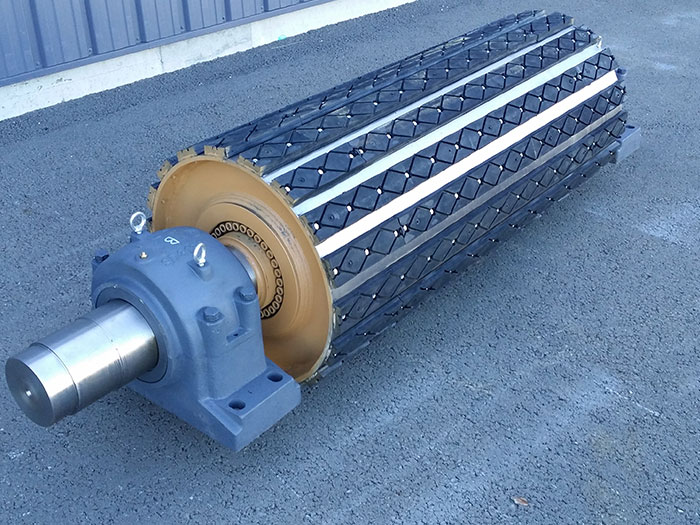

Pulley bars

Anti-skid lagging for large and heavy duty conveyor pulleys

Ruggedly designed, the anti-skid bars are made of wear-resistant rubber for long life.

Griplag

For tough conditions

The Griplag prevents slippage and is self-cleaning, preventing material build-up and misalignment.

VARIOUS LAGGING AND PREPARATIONS

Hot vulcanization

Vulcanisation is a chemical process that gives the drum pulley lagging greater tensile strength, swelling, abrasion resistance and elasticity.

Cold rubberising

Cold rubber bonding is generally used on "classic" drum pulleys for rubber coatings with smooth, diamond-shaped ceramic inserts.

Special rubberizing

Coatings such as Slide Lag, Pulleybars or Griplag are applied to conveyor drums and conveyor pulleys by mechanical assembly.

Shot-blasting

All coated conveyor pulleys are shot-blasted for improved surface preparation. This preliminary work is essential for optimum adhesion to the conveyor belt pulley.

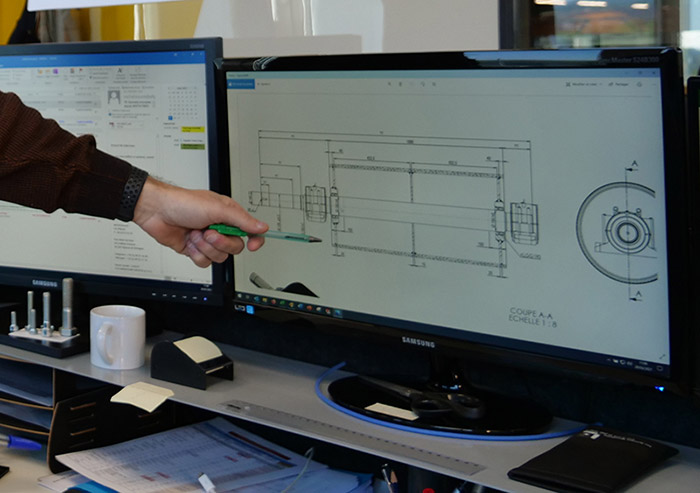

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

For over 25 years, ALTEMA has specialized in the production of conveyor drums for a wide range of sectors, including the automotive industry. This extensive experience enables our partners to obtain the best technical and economic compromise, and a drum perfectly adapted to its destination on the conveyor belt. Personalized customer support enables us to define the best technical solutions, guaranteeing perfect use and integration of the drum with the appropriate lagging.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.