Pre-treatment for conveyor pulley surface preparation

All coated drum pulley are shot-blasted for better surface preparation. This preliminary work is essential if the rubber lagging is to achieve optimum adhesion to the conveyor belt pulley. Shot blasting is a technique that consists of projecting microbeads onto the surface of an object using a shot blasting machine to modify its surface structure. This technique is used to improve the surface integrity and hardness of a material, and to improve adhesion between different adhesive layers.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

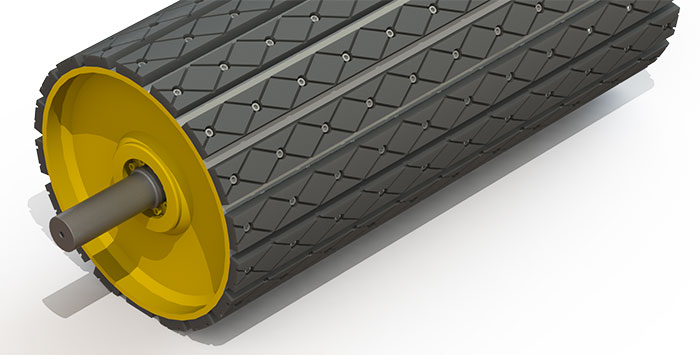

Profile types

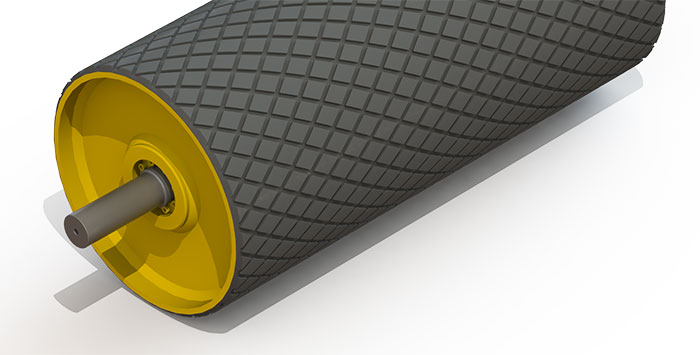

Diamond

The universal lagging

Used on deflection and take up pulley. It is also suitable for head pulley.

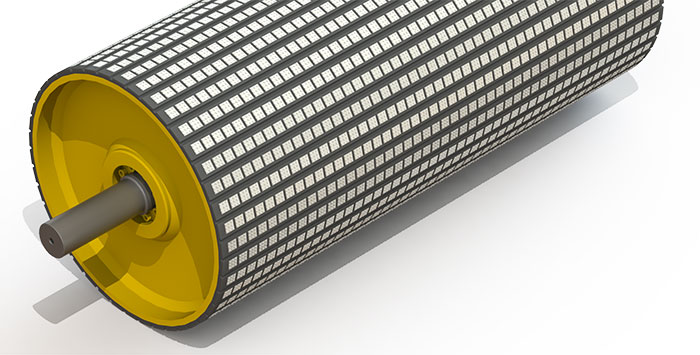

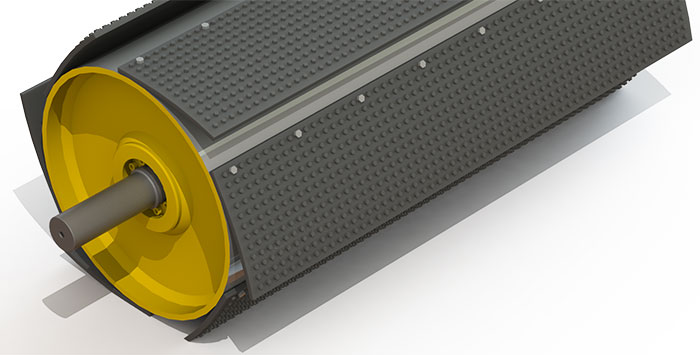

Ceramics

The high-adhesion lagging

Effective in humid environments to prevent slipping on the conveyor belt.

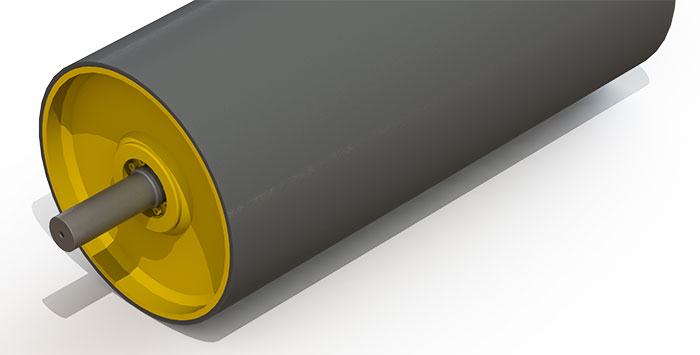

Smooth

Protective lagging

For conveyor pulleys that don’t drive the belt, to extend their service life.

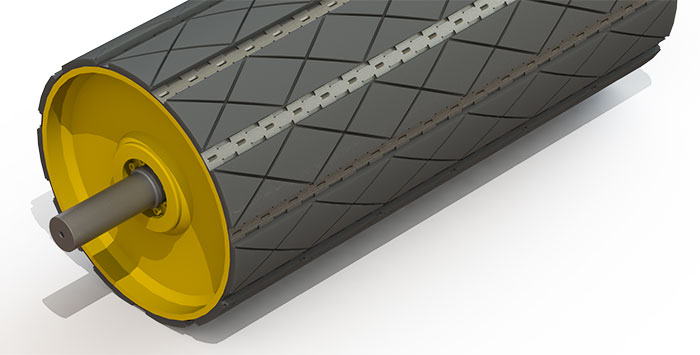

Slide Lag

For high tensile forces

Its elastomer composition gives head or drive pulleys high tensile strength.

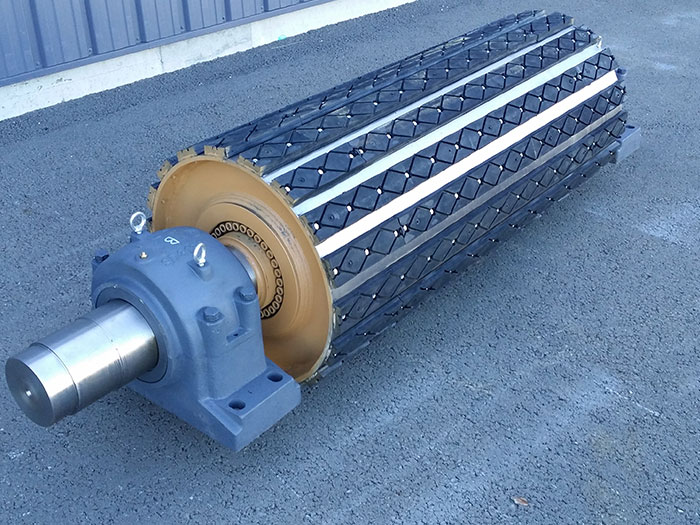

Pulley bars

Anti-skid lagging for large drums

Ruggedly designed, the anti-skid bars are made of wear-resistant rubber for long life.

Griplag

For tough conditions

The Griplag prevents slippage and is self-cleaning, preventing material build-up and misalignment.

The benefits of rubber lagging

- Bonding systems that make installing pulley rubber easy, fast and tailored to your needs.

- The lagging protect the belt and significantly improve the conveyor’s overall performance, thus extending its service life.

- They ensure that rollers and drum pulleys rotate smoothly without clogging, thus maintaining and aligning the conveyor belt.

- Rubberized pulleys protect the belt by reducing slippage between belt and pulleys.

- They reduce the belt’s operating tension, thus reducing belt elongation.

- They reduce conveyor noise and vibration.

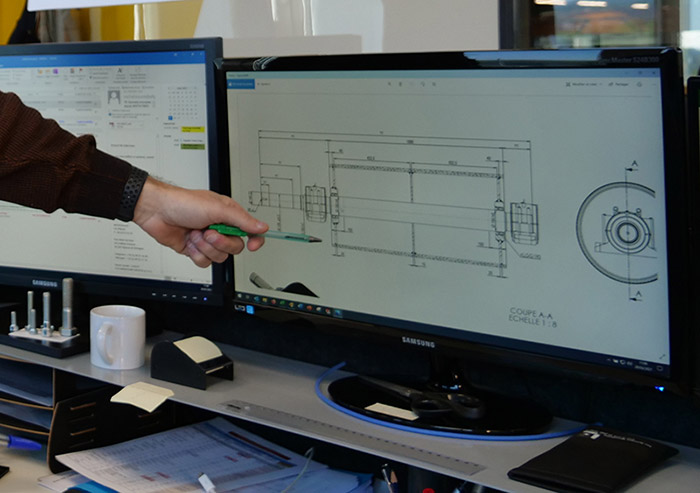

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

Since 1995, ALTEMA has been developing special belt pulleys for quarries, mines and other sectors requiring conveyor drums. The company offers a range of solutions to meet all its customers’ needs, even the most specific, by defining a conveyor drum pulley perfectly adapted to the customer’s constraints.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Different laggings and preparation

Hot vulcanization

Vulcanisation is a chemical process that gives the drum greater tensile strength, swelling and abrasion resistance, as well as greater elasticity.

Cold rubberizing

Cold rubber bonding is generally used on “classic” drum pulleys for rubber coatings with smooth, diamond-shaped ceramic inserts.

Special rubberizing

Laggings, such as Slide Lag, PulleybarsⓇ or GriplagⓇ, are applied to drums and pulleys by mechanical assembly.