Function of Take up pulley on conveyor belt

To enable a conveyor to manage belt tension, it can be fitted with an assembly known as a “tension group”. This take up pulley unit adjusts belt tension according to the load exerted by the conveyed material, as well as to the forces generated by stop/start operations.

This group of conveyor pulleys is made up of 2 bend pulley (or “deviation drums”) to deflect the belt from the drive drum to the take up pulley. The take up pulley then returns the belt to the 2nd bend pulley in the direction of the tail pulley.

The take up drum pulley is suspended in vacuum with an added load to increase its weight. It enables even tension to be applied to the conveyor, with the option of raising or lowering the belt according to belt load and applied forces.

Implementation

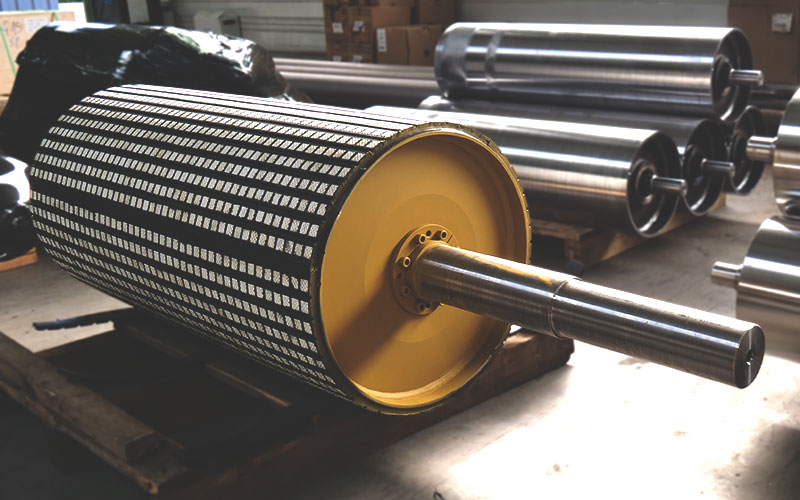

The bend pulleys and take up pulley are machined with a convex shape. This process maintains perfect centering of the conveyor belt.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

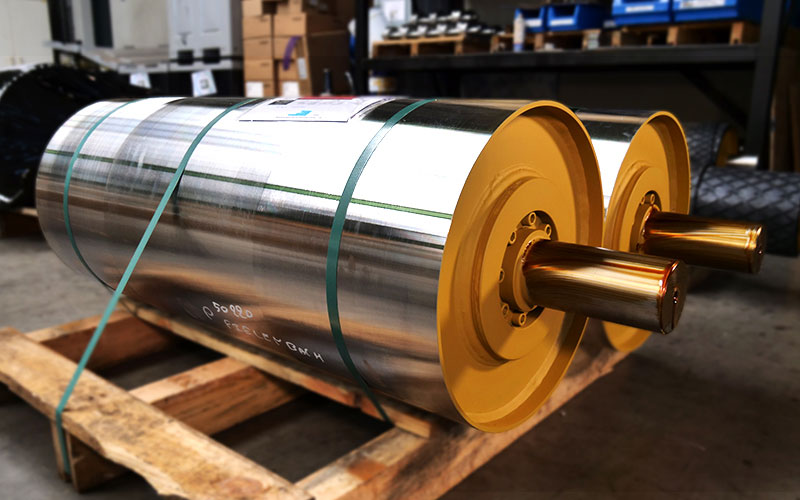

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

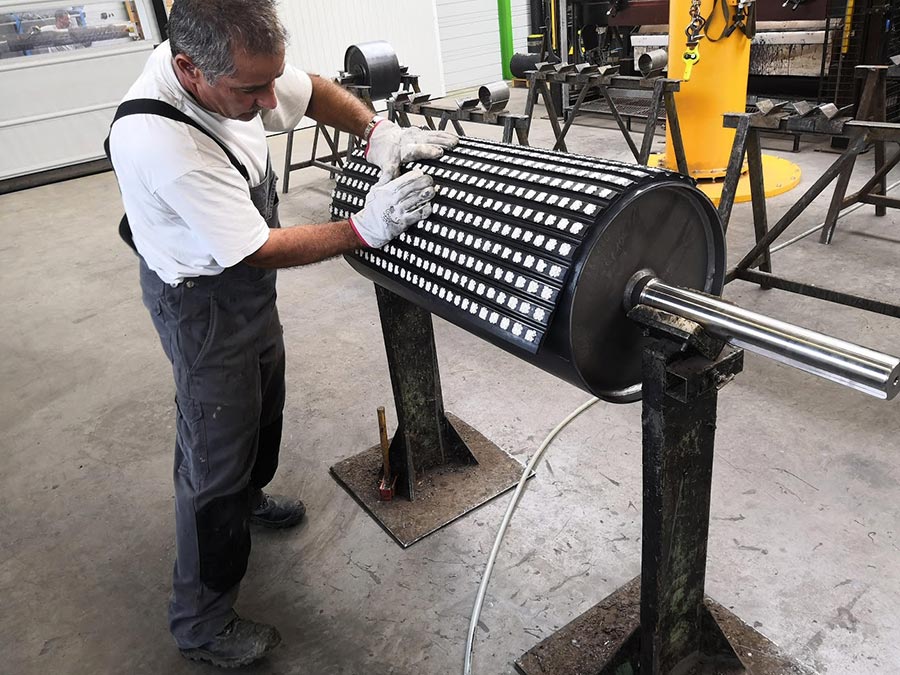

Lagging for conveyor take up drum pulley

From the choice of lining material, to the various lagging technologies, right through to the preparation phases, ALTEMA puts its 25 years of know-how at the service of its customers. Discover our lagging solutions for take up pulleys.

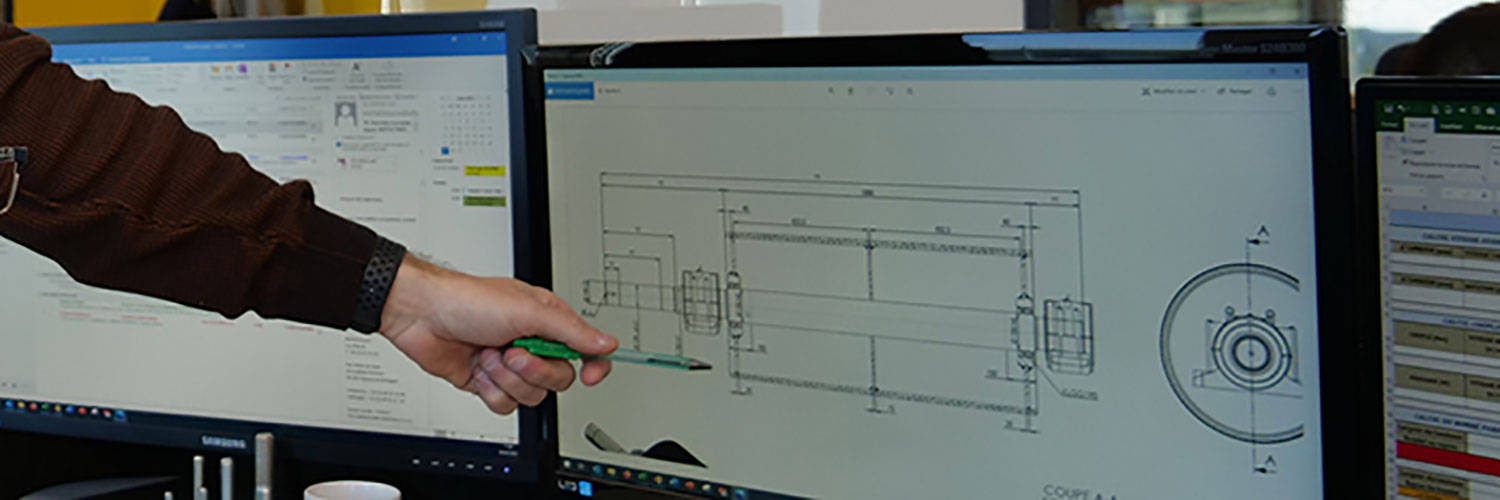

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

A recognized player in the production of conveyor take up pulley or take up drum for demanding sectors such as the automotive industry, ALTEMA today supports its partners in certifying the best technical and economic compromise, fully adapted to each application. The aim is to guarantee optimum adaptation of the pulley to the conveyor, while ensuring long service life.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Other classic conveyor pulleys

tail pulley

Usually positioned on the other side of the control section on a conveyor belt, this drum pulley is used to return the control section to its original position.

Head pulley

The head pulley or drive drum is the drum pulley that sets the conveyor belt in motion.

Snub pulley

The snub pulley increases the belt’s contact surface with the nearest drum.