The Tail Pulley: Function in a Belt Conveyor System

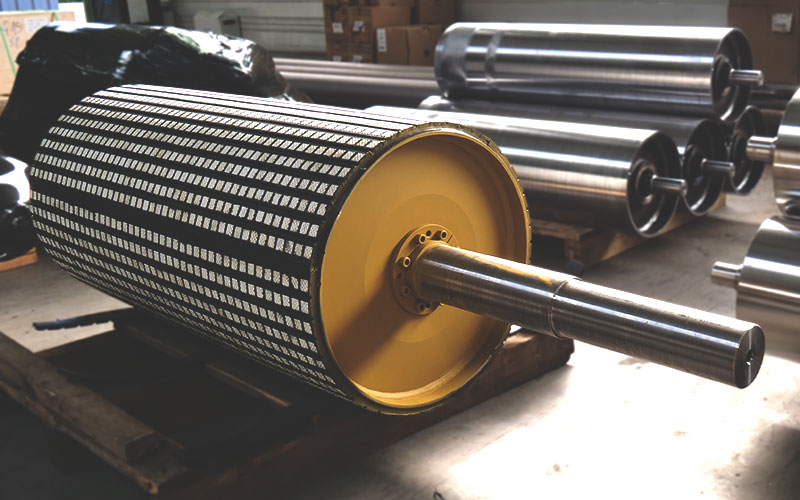

Positioned opposite the head pulley, the tail pulley redirects the belt back to the drive section while maintaining its alignment. It also helps adjust the belt tension based on the load being transported and operating conditions. This makes it a key component for the efficient operation of a conveyor belt system.

A Tailored Solution for Every Application

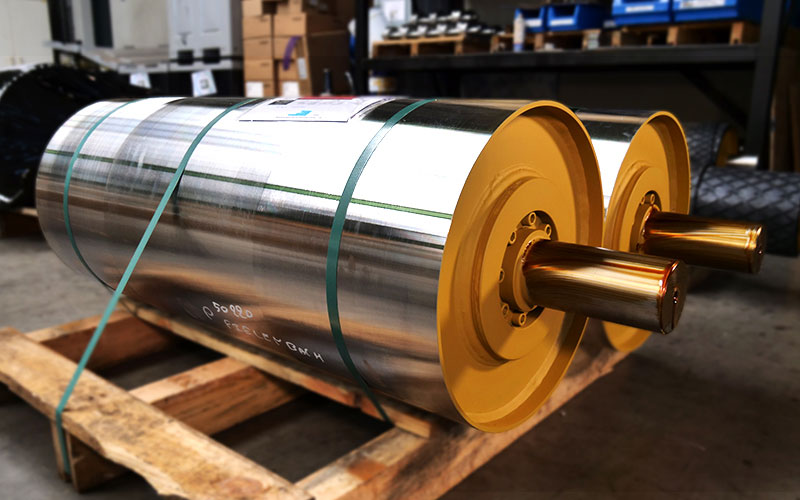

Whether referred to as a return pulley or tension pulley, this equipment is designed to meet various industrial demands. ALTEMA offers precisely machined tail pulleys, often with a crowned profile to ensure optimal belt alignment during operation. This design helps reduce premature wear of the conveyor and minimizes maintenance interruptions, ensuring the continuity of your operations.

Why Choose ALTEMA?

With 25 years of experience, ALTEMA is your trusted partner for custom-made conveyor solutions. Our tail drum pulleys are built to deliver durability and reliability while adapting to the specific requirements of each installation. Optimize your conveyor system with our custom tail pulleys.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

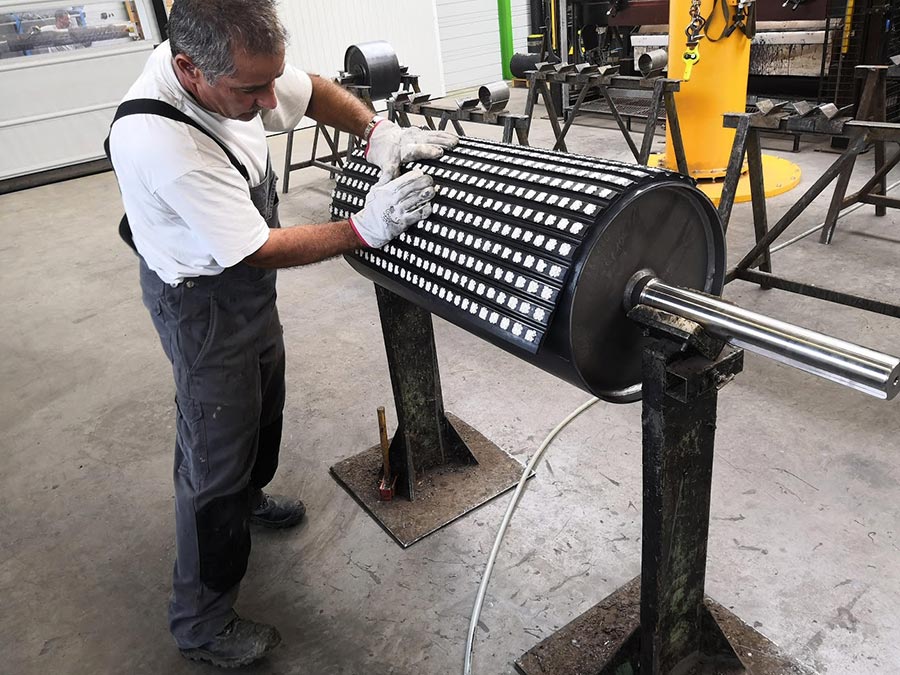

Lagging for Return Pulley

Return pulleys, essential for the proper functioning of belt conveyor systems, can be supplied without a coating but are generally equipped with lagging to extend the lifespan of both the belt and the drum pulley. In most cases, a smooth rubber lagging is applied, as the primary role of this type of Conveyor pulley is to ensure the belt’s return without generating traction. For applications where belt tension is critical and essential, the tension pulley may require a specific lagging to prevent excessive slippage. This not only ensures smooth operation of the belt conveyor but also effectively protects the belt under high tension. In such cases, rubber coatings such as Pulley Bars and Griplag are more suitable.

ALTEMA offers a wide range of coating and lagging solutions to meet the specific needs of each industrial installation. Our drum pulley experts assist you in selecting the ideal lagging to ensure the reliability and efficiency of your tension drum pulleys and return pulleys, thereby enabling optimal performance of your conveyor system.

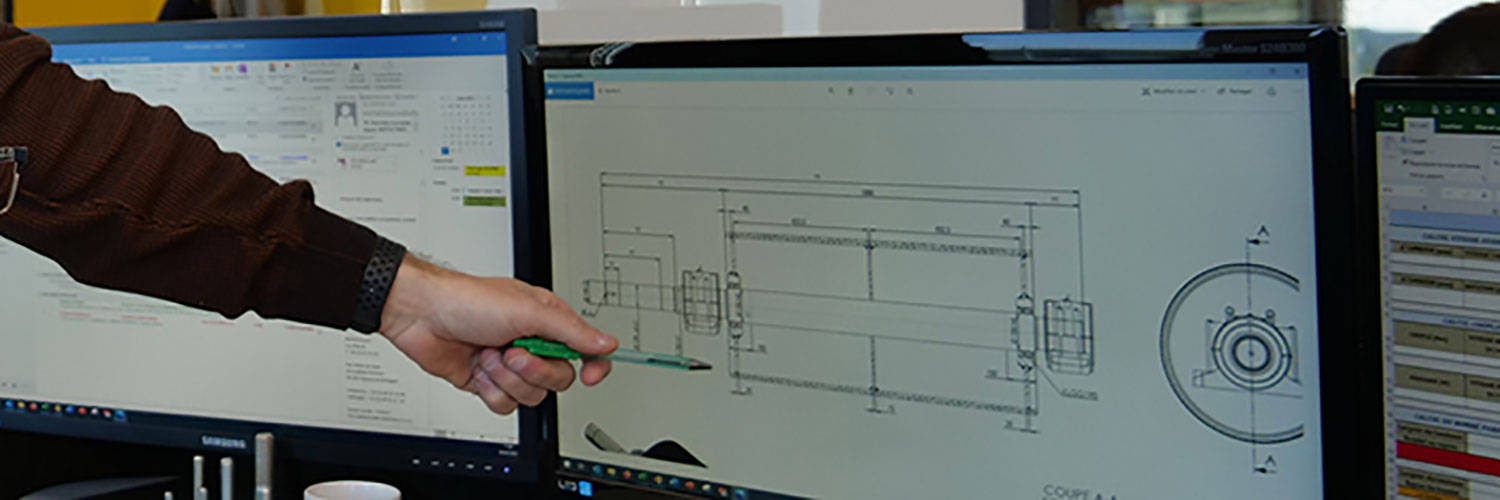

Technical support in defining your Return Drum pulley

At ALTEMA, we understand that every industrial project is unique. That’s why we offer tailor-made return drum pulleys, precisely adapted to your technical specifications. With extensive experience in designing conveyor drums for sectors such as quarries, mining, and recycling, we efficiently support our clients in achieving their goals. Our technical team, equipped with advanced calculation software (RDM, 3D CAD), performs precise dimensioning for each conveyor pulley to ensure they fully meet the technical requirements of your installation. This enables us to guarantee optimal quality for our tail pulleys and their seamless integration into your conveyor systems.

The ALTEMA team is at your disposal to define the characteristics of your drums, ensuring the long-term smooth operation of your facilities.

Altema services

RDM DIMENSIONING

ALTEMA’s Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Other classic conveyor pulleys

Drive Pulley

ALTEMA offers robust drive pulleys or head pulleys designed to handle heavy loads and operate in challenging industrial environments, such as quarries or mines.

Snub pulley

The snub drum maximizes the contact surface between the belt and the drive or tail pulleys. This prevents slippage and optimizes the performance of the conveyor belt system.

Take up pulley

Particularly important in long conveyors or those transporting variable loads, the take up pulley automatically adjusts the tension to prevent slippage or belt misalignment.