Function of Snub pulley on conveyor belt

The snub pulley tensions the conveyor belts, forcing the belt to wind a little more onto the nearest drum. The sole aim is to increase the contact surface between the belt and the drum pulley concerned. On a conventional conveyor, for example, the winding angle is around 180°. With a snub pulley, this winding can be increased to 210°. It is often placed just after the head pulley (the drive drum), but can also be placed just before the tail pulley.

Implementation

As a general rule, this type of drum needs to be cylindrically machined, as its function does not require belt centering, which is carried out on the other conveyor stations.

Need for

Technical advice?

Call our drum experts

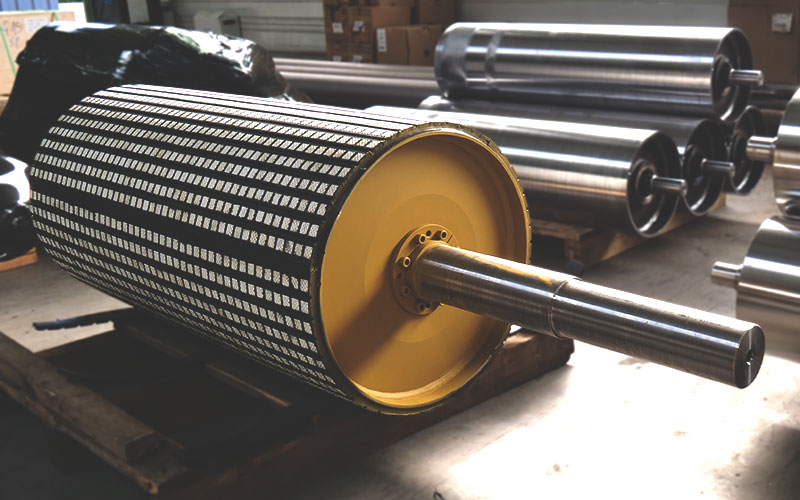

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

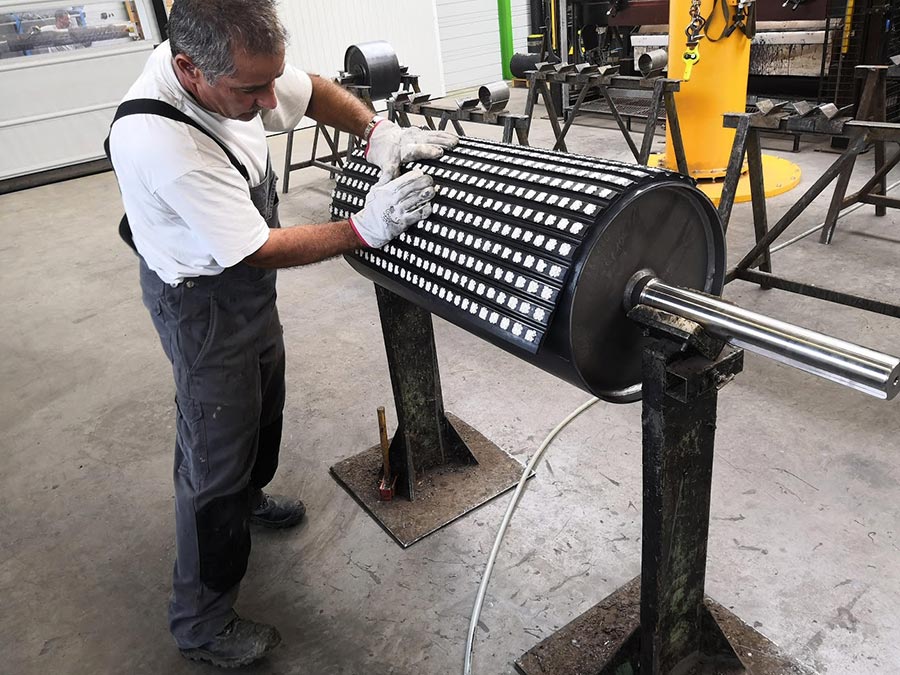

Lagging for conveyor snub drum pulley

The special feature of the snub drum pulley is that it is located on the “dirty strand” of the belt. When lined, it’s best to use an anti-clogging lagging to prevent material build-up. This surface has no grip profile, as it has no driving function. If this is not the case, a rubber with a diamond or ceramic profile should be used to ensure a firm grip on the drum. Contact our team to find out more about the different lining and lagging solutions offered by ALTEMA.

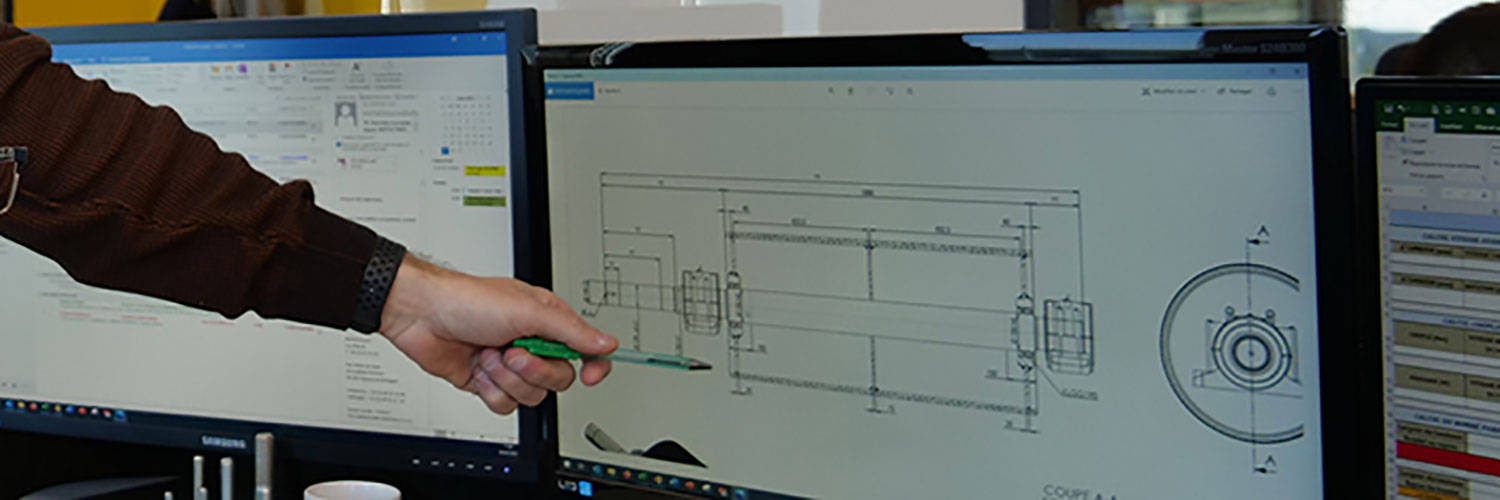

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

For over 25 years, ALTEMA has been helping its customers to define their snub pulley. ALTEMA’s customers operate in a wide range of sectors, including mining, quarrying, recycling, food processing, fertilizers and chemicals. ALTEMA’s role is to help its customers optimize the design of their conveyor pulleys, right from the design phase. The aim is to achieve the best technical-economic compromise and ensure a long product life.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

The different types of conveyor pulley

tail pulley

Usually positioned on the other side of the control section on a conveyor belt, this drum pulley is used to return the control section to its original position.

Head pulley

The head pulley or drive drum is the drum pulley that sets the conveyor belt in motion.

Take up pulley

The take up pulley is used to adjust belt tension according to the load to be conveyed.