Drum Pulleys for every function

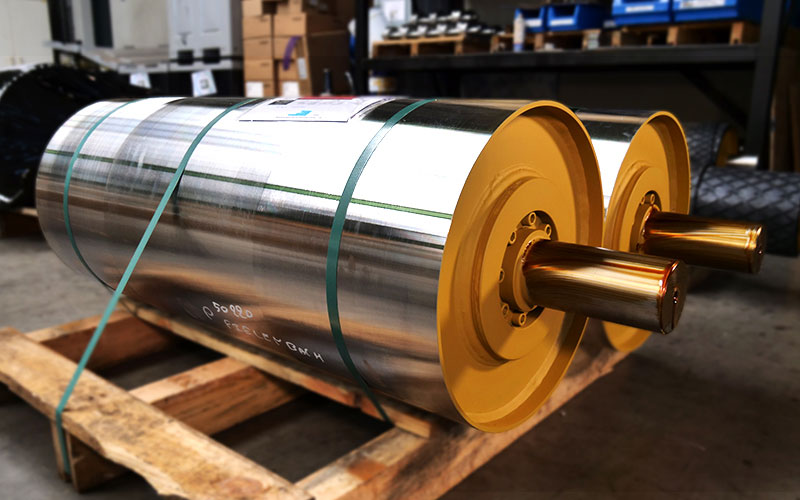

At ALTEMA, we design and manufacture custom conveyor drum pulleys, tailored to the specific requirements of each industrial project. Whether for standard conveyors or heavier conveyor systems used in demanding environments such as mines, quarries, or ports, we are capable of efficiently meeting all demands.

With over 25 years of experience and our modern production facilities, we produce a wide range of conveyor pulleys: drive or head pulleys, tension or return pulleys, snub pulleys, or even counterweight pulleys. Made of steel or stainless steel, coated or uncoated, bi-conical or cylindrical, our teams are at your disposal to develop the most suitable technical solution for your needs.

Conveyor pulleys of all dimensions

We offer customized solutions covering a wide range of dimensions, from conveyor drum pulleys with diameters ranging from 88 to 600 mm for standard applications, to large-diameter models designed for heavy-duty use. Each conveyor belt drum can be equipped with different types of shaft/flange connections: removable tapered hubs, UCFC flange bearings, or clamping elements.

With over 10,000 conveyor belt pulleys produced each year, ALTEMA stands out as a trusted partner for all industries using conveyor belts. We work closely with our clients at every stage of their project to define the most suitable conveyor drum pulley for their operations, while ensuring reliable products with a long service life and compliance with safety requirements.

Need for

Technical advice?

Call our drum experts

A range of drum pulleys for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor pulley and handling drum pulley requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drum pulleys per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum pulley ? Send us your pre-filled request for a quick quotation using ALTEMA drawings.

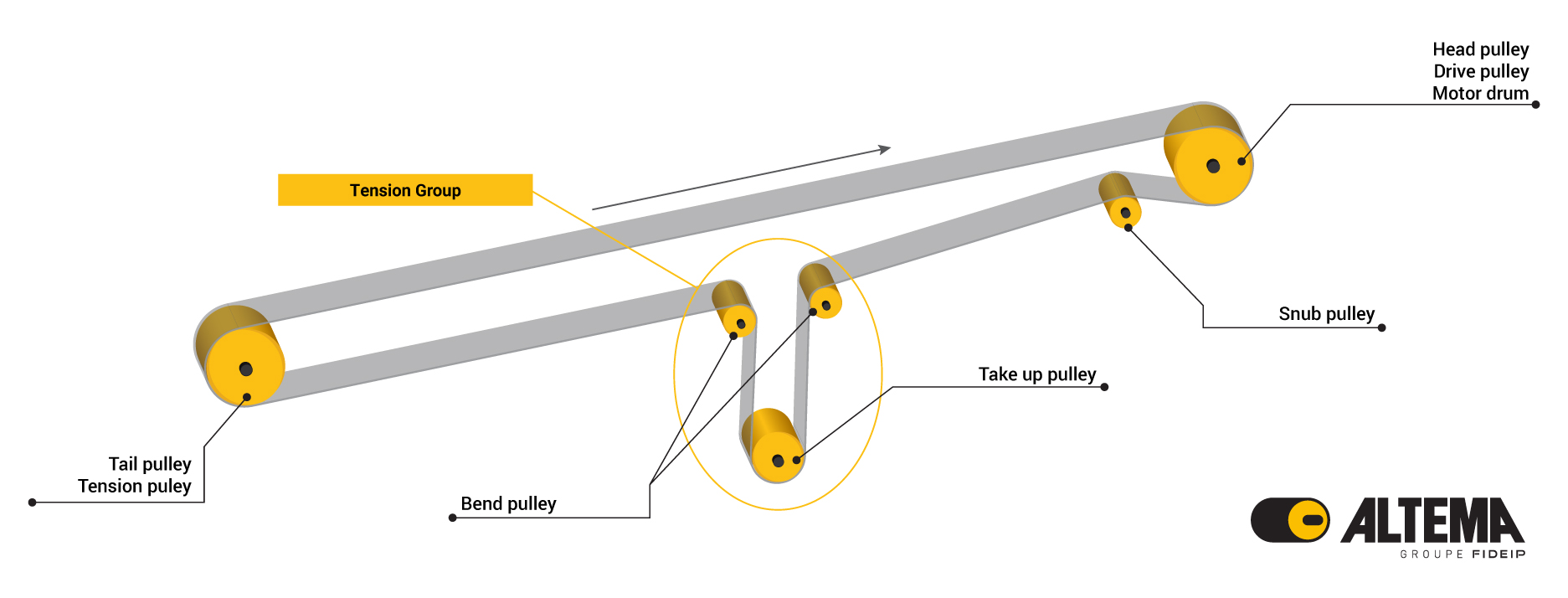

Simplfied drawing of a belt conveyor

tail pulley

The tail pulley, usually located opposite the drive section, ensures precise alignment of the conveyor belt and maintains optimal tension, thereby reducing the risk of premature wear.

Head pulley

The head pulley, also known as the drive drum pulley, sets the conveyor belt in motion. We offer motorized pulleys with various types of coatings to optimize traction and minimize wear.

Snub pulley

The snub drum pulley is used to increase the contact surface between the conveyor belt and the nearest drum. It plays an essential role in ensuring effective traction and constant tension.

Take up pulley

The take-up pulley is used to adjust the belt tension based on the load being transported. This ensures smooth conveyor operation and helps prevent breakdowns caused by improper tension.

Lagging for conveyor take up drum pulley

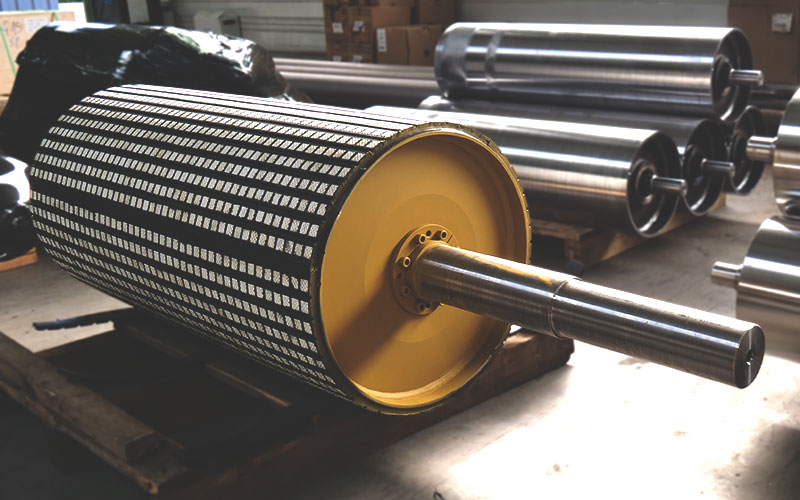

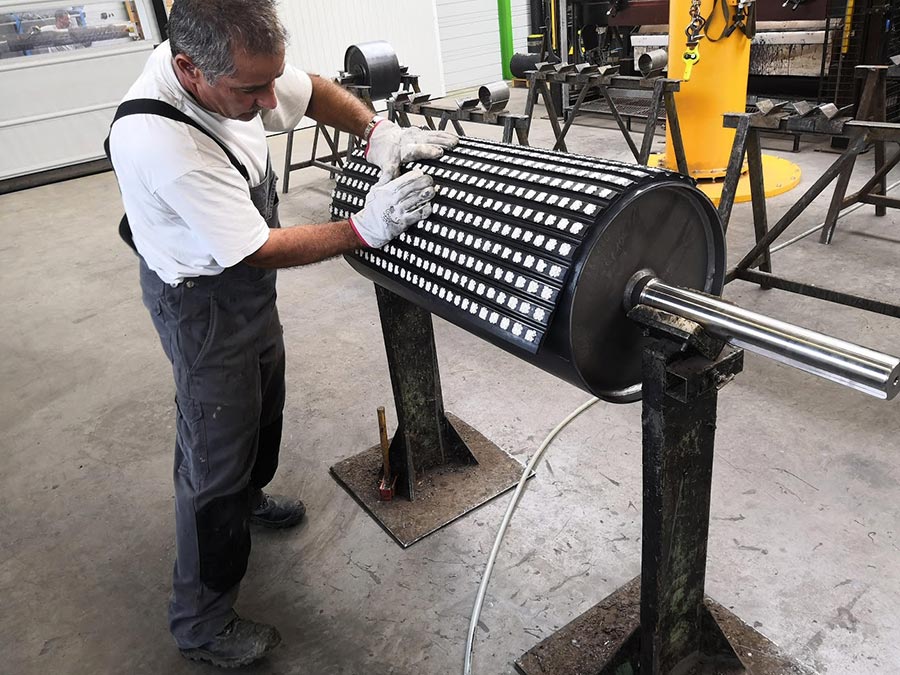

To improve traction and protect the conveyor belt, ALTEMA offers several coating solutions for your conveyor belt drums. With 25 years of experience, ALTEMA’s expertise covers the coating profile, the lining technology used, and the preparation processes for both the drum pulley and the coating.

The coatings offered range from smooth rubber to ceramic coating, including various products such as diamond-patterned ISO 284/340, and many other options. Our solutions ensure increased durability and a long service life for conveyor drums. Depending on your needs, we also use cold bonding or hot vulcanization techniques to guarantee optimal adhesion of the coating

Shaft coupling systems for conveyor belt drum

The connections between the drum and the shaft are a crucial element in ensuring the robustness and reliability of the conveyor system. ALTEMA offers various options such as VECOBLOC removable hubs, clamping elements, UCFC flange bearings, and welded flange connections.

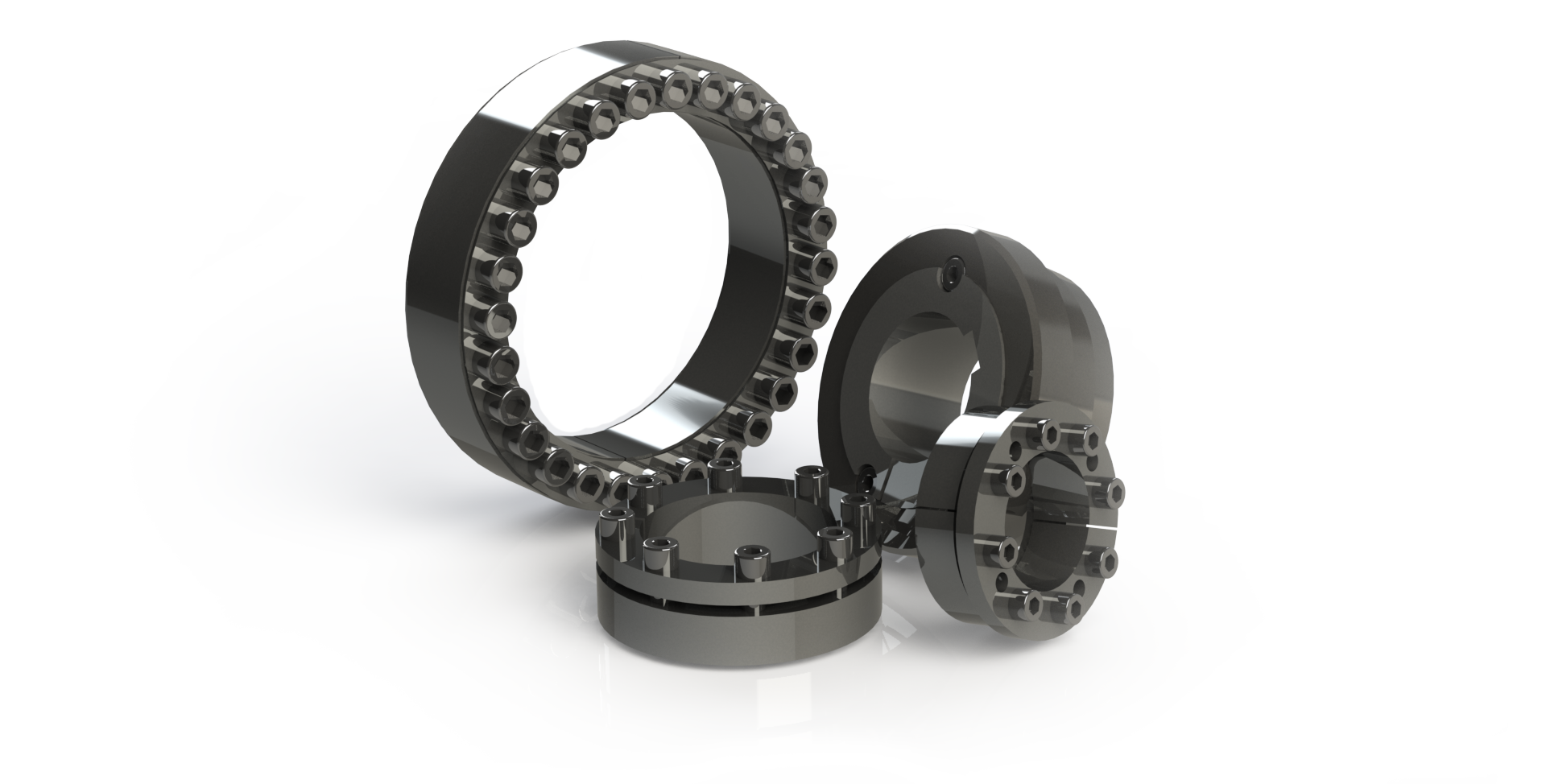

Clamping elements

Clamping elements operate by using the radial deformation of tapered components that form their head. When the tightening torque is applied to the screw, an axial movement is generated, allowing the conical parts to make contact. This mechanism produces a compressive force that ensures a solid connection between the drum and the shaft. The advantages of clamping elements include eliminating play between the drum pulley and the shaft and distributing the load evenly across the entire shaft diameter. This reduces wear and increases the lifespan of the components.

Universal hubs type VECOBLOC

VECOBLOC removable hubs, also known as TAPERLOCK, are detachable connections that allow a conveyor belt drum to be fixed to its shaft without the need for specific tools. This system provides a good alternative to clamping elements for users who wish to maintain a keyed connection. The advantage of this coupling system is the wide range of models available to suit various industrial applications.

Why choose ALTEMA for your conveyor drum pulleys?

ALTEMA stands out for its technical expertise, personalized support, and the quality of its products. Our custom solutions and commitment to our clients allow us to position ourselves as a reliable partner for the manufacturing of your conveyor belt or elevator drum pulleys.

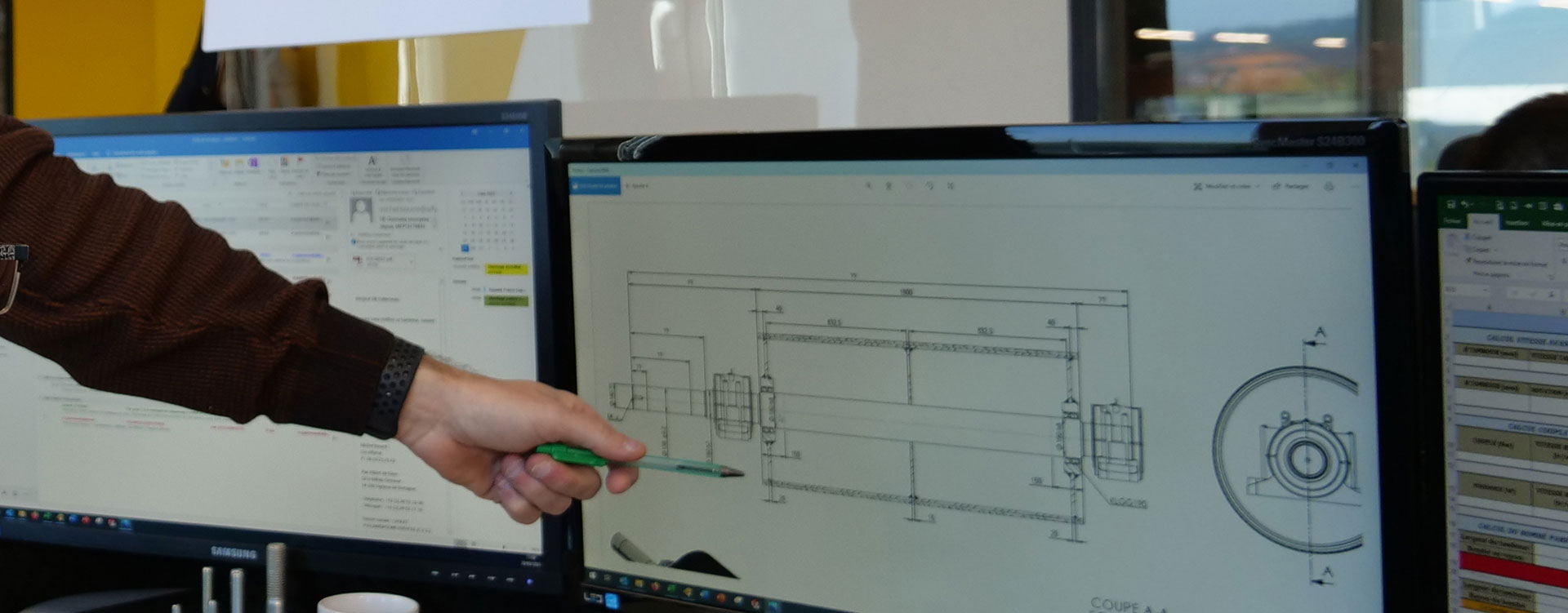

Technical support in defining your products

Since 1995, ALTEMA has produced hundreds of thousands of conveyor pulleys for industries such as quarries, mines, and other sectors requiring handling and conveyor drums. Our in-house design office and technical teams oversee every step of the process, from design to production, including precise sizing of conveyor drum pulleys using advanced 3D CAD software. This allows us to effectively support our clients in designing solutions tailored to all configurations and technical requirements.

Quality control and compliance with standards

At ALTEMA, we are committed to providing drum pulleys with a high level of reliability. Each drum undergoes strict quality control at every stage of its manufacturing process. This allows us to validate compliance with the dimensional tolerances defined during design, guarantee high-quality drums, and ensure complete customer satisfaction.

Our production processes are not limited to quality control; they also comply with environmental and safety regulations.

Responsiveness with ALTEMA service

Thanks to our ALTEMA service, we can produce and ship drums within short timeframes. This service is particularly suited for industries that cannot afford prolonged interruptions in their production. Do you urgently need to replace a drum (ø114 to 508 mm)? ALTEMA is committed to meeting your needs as quickly as possible.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.