Our know-how

For over 25 years, Altema has been manufacturing custom conveyor pulleys, designed to meet the specific needs of various industries such as mining and quarrying, waste management, food processing, agriculture, port and airport logistics, automotive, fertilizers, and chemical industries.

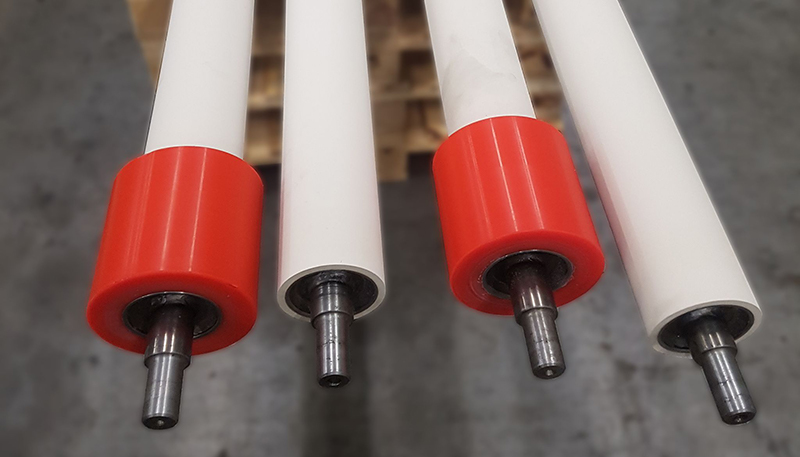

With our efficient production equipment and expertise in conveyor belt pulley manufacturing (drive pulley, tail pulley, wing pulley, self cleaning pulley, etc.), we ensure products that are reliable, durable, and well-suited to each client’s application, considering the operational constraints and performance requirements of the conveyor belt.

By choosing Altema, you are opting for a trusted partner capable of delivering tailor-made solutions to optimize the performance of your conveyor belt. Whether you need drive pulleys, tail pulleys, or snub pulleys made from steel or stainless steel, with rubber or ceramic lagging for enhanced wear resistance, we have the right solution for you.

Explore our wide range of conveyor pulleys, including Head pulleys, Tension pulleys, Snub pulleys, Take up pulleys, Bend pulleys, Wing pulleys, elevator pulleys and custom-made conveyor drums… We also offer conveyor bearings and clamping systems. To best meet our customers’ needs, the company additionally provides customized services: coating, lagging, dimensioning, balancing and maintenance.

ALTEMA

NEED FOR TECHNICAL ADVICE ?

Contact us

Our Conveyor drum pulleys

From standard to highly specific

Standard conveyor Pulleys

Large diameter Drum Pulleys

Special Drum pulleys

Custom-made Drum Pulleys

Bearing for conveyor belt pulley

coating and lagging

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drum pulleys and elevator pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor pulleys, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.

Conveyor belt pulleys for all industries

- Quarries and mines

- Waste collection center

- Agri-food

- Automotive

- Fertilizers and chemicals

- Airport port

- Agriculture

- Steel industry

Quarries and mines

The mining industry is subdivided into a wide range of sectors, including the extraction of coal, metallic minerals, precious stones and non-metallic minerals. Raw materials are processed to meet a wide range of needs, particularly in the manufacturing, construction and infrastructure sectors. Whether at the time of extraction, or for the processing of these raw materials, numerous belt conveyors are required for these activities.

Waste collection center

Waste sorting methods vary according to the nature of the waste and the characteristics of the collection. To minimize the amount of waste going to landfill or incineration, ambitious new recycling and recovery targets have been set. ALTEMA conveyor belt drums can be found on sorting and processing systems for selective collection, household waste, industrial waste, composting, CSR processing, Machefer, sorting of CIW, WAS and rubble.

Agri-food

For 25 years, ALTEMA has been supplying conveyor pulleys for the processing of raw materials used in the food industry. This experience enables us to meet every requirement, from standard drum pulleys to squirrel-cage drums. ALTEMA conveyor drums are used on conveyors or bucket elevator to transport cereals, sugar, salt, coffee and flour.

Automotive

In the automotive conveyor systems sector, conveyor belts have a wide variety of applications. For automotive parts and assemblies, conveyor belts are used to transport stamped parts at high speed and with maximum safety. The type of belt required depends on the material being conveyed.

Fertilizers and chemicals

ALTEMA supplies conveyor belt pulleys with loading hoppers or elevators in the fertilizer industry. From grasshopper conveyors to large conveyor systems for phosphate mining, ALTEMA can meet all the demands of these demanding sectors.

Port / Airport

ALTEMA supplies conveyor belt drums for handling bulk materials and general cargo. ALTEMA provides systems to simplify loading and unloading operations. The aim in these sectors is to keep vessel downtime to a minimum. The drum pulleys must be able to withstand the harsh climatic conditions associated with their seaside location (wind, salt, etc.).

Agriculture

ALTEMA is active in the agricultural sector, particularly in the handling of cereals on conveyor belts or bucket elevators. ALTEMA conveyor drums are installed on belt conveyors, while bucket elevator pulleys are installed in silos, both used to transport raw materials in the agricultural sector.

Steel industry

The iron and steel industry produces pig iron and ships it to foundries where it is used to produce cast iron or steel. ALTEMA conveyor pulleys are installed on various systems: rolling mill plate conveyors, aluminum scrap belt conveyors, foundry raw parts conveyors.

Quality control and warranty

Since its founding, Altema has been committed to upholding the highest quality standards. The expertise of our teams in conveyor drum manufacturing, combined with our ongoing investment in production technologies, allows us to deliver reliable conveyor pulleys that are durable and compliant with industry standards

Each industrial drum pulley we manufacture is subjected to a thorough quality control process. At every stage of production, from shaft machining to the assembly of bearings and the application of lagging, checks are performed by experienced operators to ensure product reliability. A dimensional inspection is also conducted on the entire part before shipping.

Altema Our mission

In over 25 years, Altema has earned the trust of many clients across industries requiring bulk handling. Thanks to our modern and efficient production equipment, which benefits from regular yearly investments, Altema is capable of meeting both standard and highly specific demands for conveyor pulleys and material handling drum pulleys, tailored to precise specifications.

With a production facility spanning over 4000 m², we can quickly manufacture all types of industrial drum pulleys, with or without lagging, with welded or removable shafts, with or without bearings.

Technical expertise and custom-made solutions for your conveyor pulley needs

For each project, we offer a precise evaluation of the operating conditions of your conveyor systems. Through close collaboration with your technical teams, we define the optimal characteristics for your conveyors pulleys, including the choice of materials (stainless steel, steel), the type of lagging, and the required dimensions.

Reactive and tailored maintenance solutions

To ensure the continuity of your operations, we also offer reactive maintenance services through, which allows for fast repairs of your conveyor pulleys, minimizing production downtime.

Key figures

1995

Creation of the company

10 000

drum pulleys per year

+500

SATISFIED CUSTOMERS

The energy of a group

ALTEMA is part of the Vendée-based industrial group FIDEIP.

Labeled FRENCH FAB, this group brings together more than 400 talents and currently consists of 14 companies and brands specialized in five business sectors: Process & Special-purpose Machines, Industrial Robotics, Conveying Solutions, Precision Mechanics, and Capital Goods.

The FIDEIP Group promotes the fulfillment of men and women within organizations, through team diversity, employee commitment and talent development.

News What’s new at Altema?

A drive drum for conveying raw materials

See more

Feb 16, 2024

Drums for transporting plasterboard.

See more

Feb 16, 2024

Recycling production waste at ALTEMA

See more

Feb 16, 2024

A skimmer drum for a sorting center.

See more

Feb 16, 2024